Iron ores

Manganese Ores

Gold Ores

Lead-zinc ore

Copper ores

Tin Ores

Silver ores

The project general contracting refers to the project contracting enterprise that undertakes all the work in all stages of the project, including design, budget, equipment and material procurement, construction, commissioning and acceptance, and finally submits a project that meets the use functions and conditions to the customer, and assumes all the responsibilities for the quality, progress, cost and safety of the project.

We have accumulated rich practical experience and reached cooperative relations with more than 1000 customers in more than 30 countries and regions to provide them with complete sets of solutions and services covering the whole life cycle of products

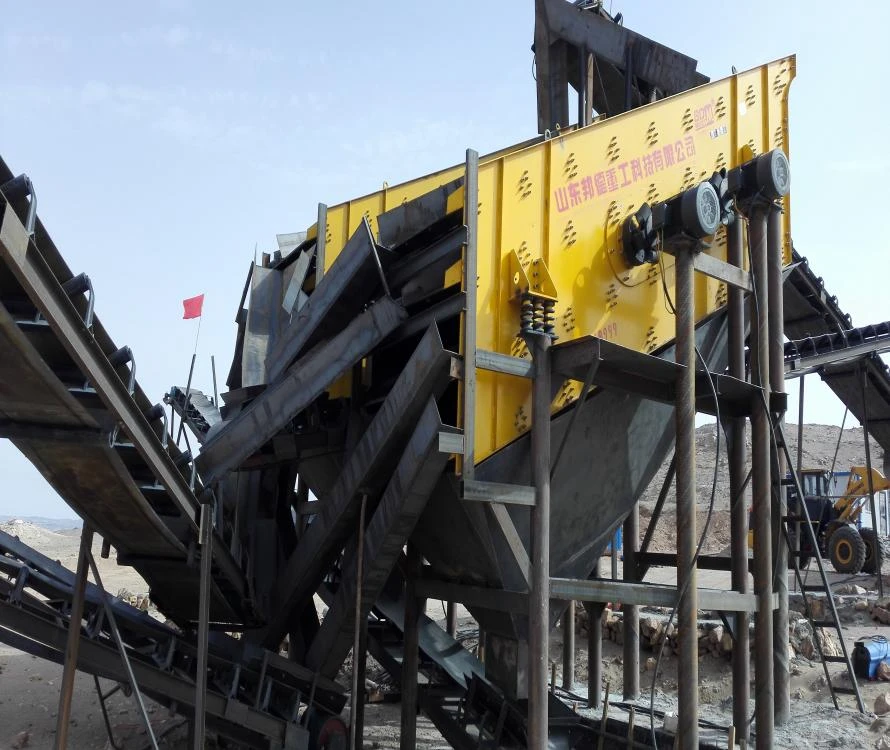

Each kind of material processing equipment has its special functions, and we should also make them play the greatest role in the material processing plant. It is also convenient for our customers to select and determine the appropriate equipment according to their special material processing field.

Generally, the ore is broken to 6~0mm or 10~0mm, and then grouped. The coarse grade is eliminated, and the fine grade is sent to the shaking table for separation.

The 0-12 mm ore screened by the vibrating screen shall be uniformly sent to the pulverizer for grinding and screened by the spiral classifier. The unqualified ore shall be sent to the pulverizer for grinding;

The material after grinding is graded by the powder concentrator, and the unqualified powder is graded by the powder concentrator and then returned to the main machine for re-grinding.

The fine ore meeting the beneficiation requirements is sent to the magnetic separator for strong magnetic separation to remove impurities, and the obtained ore powder is sent to the dryer for drying to obtain concentrate.