Mine industry

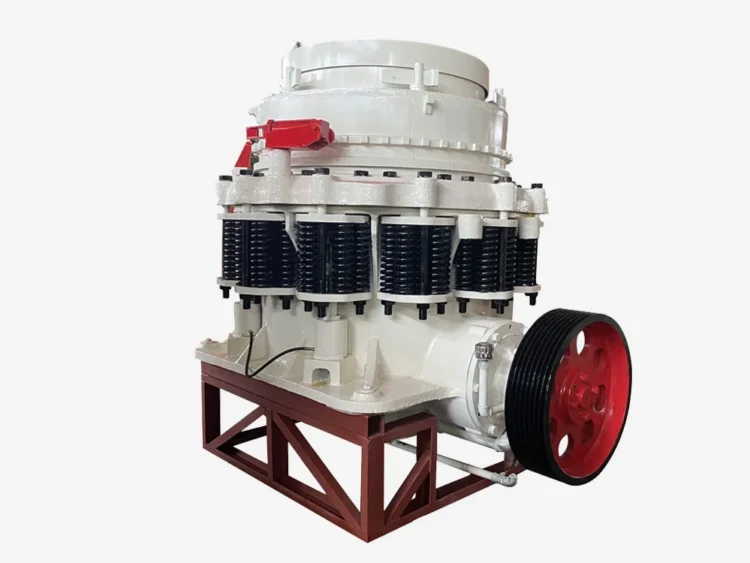

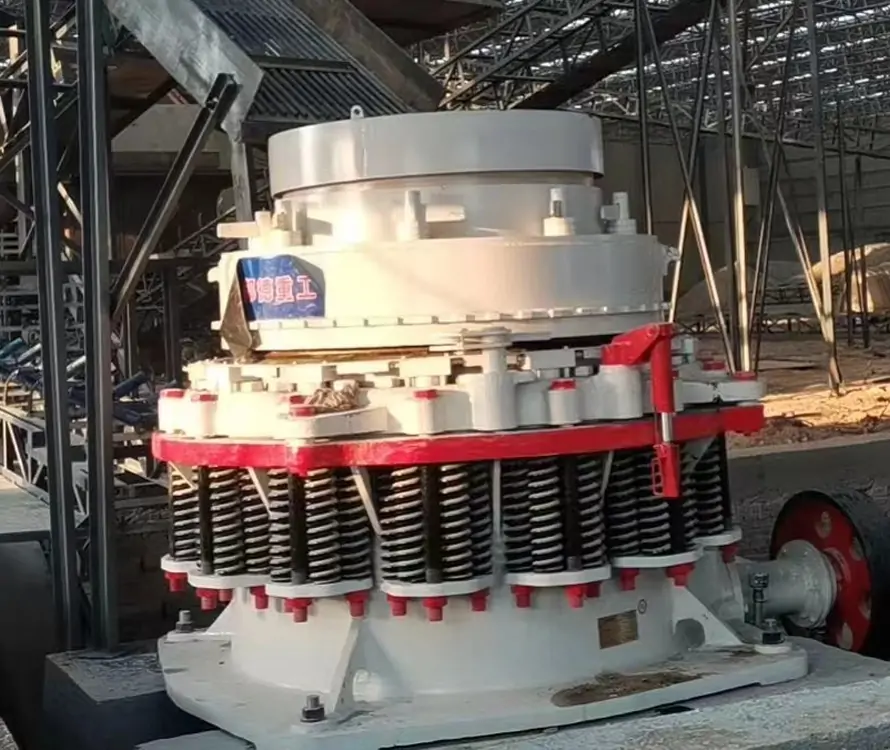

According to the type and nature of the ore, there are many different technological processes. For iron ore, people use a three-stage crushing process widely. They are coarse crushing, medium crushing, and fine crushing. Jaw crushers are used for coarse crushing. Cone crushers are used for medium and fine crushing. The ore is broken firstly, then through medium and fine crushing into a material particle size suitable for entering the vertical shaft crusher and ball mill.

In the iron ore crushing production line, we want to improve the production efficiency of iron ore and reduce production costs. It is necessary to crush the iron ore as finely as possible. The best is to smallest particle size to achieve more crushing and less grinding. It has strict requirements on the quality and crushing capacity of the crusher.

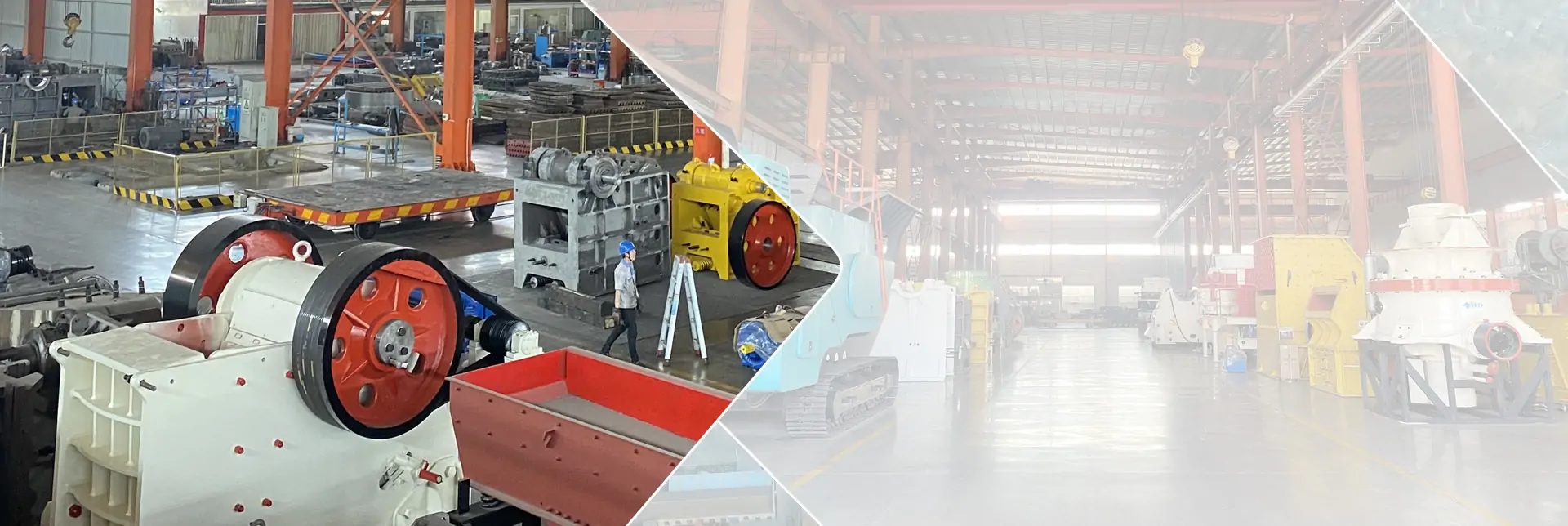

Metal Ore Production Line

It is used for crushing, screening, and grinding iron ore, manganese ore, gold ore, copper ore, etc.

Producing line configuration: it consists of jaw crusher, cone crusher, vertical shaft crusher, ball mill, vibrating feeder, and vibrating screen.

Iron ores

Manganese Ores

Gold Ores

Lead-zinc ore

Copper ores

Tin Ores

Silver ores

Magnetite

Related equipments

success cases

Iron ore

The iron ore crushing production line is made of a 6016 GZD feeder, an 1114 jaw crusher, and two S240 spring cone crushers. This production line can guarantee an output of 500 tons per hour. We can add a vertical shaft sand-making machine, ball mill, and other equipment after the spring cone if needed.

Metal Ore Production Process

Each material processing equipment has its particular function. We make them play the best role in the material processing plant. It is convenient for customers to select and determine the appropriate equipment according to the special material processing field.

Stage 1: feeding

Crush ore to 6~0mm or 10~0mm, and group it into coarse and fine grade. The coarse grade is eliminated. The fine grade is sent to the vibrating table of vibrating feeder for separation.

Stage 2: primary crushing

The mineral processing plants generally use jaw crushers to break down large pieces of ore into suitable sizes.

Stage 3: secondary and tertiary crushing

We use cone crusher to do secondary and tertiary crushing to get the required size.

Stage 4: screening

Screen the fine ores and obtain different sizes of ore materials.

Get solutions and prices now!

Leave your message here, we’ll reply to you immediately.