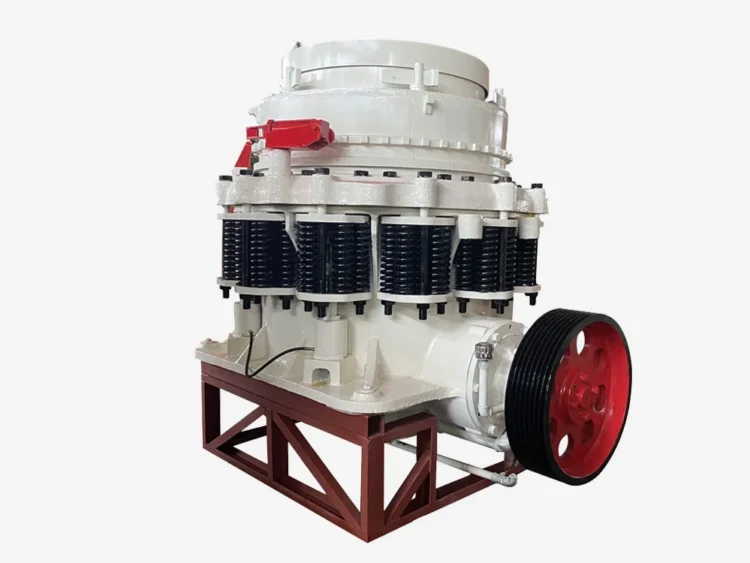

Cone Crusher For sale

The cone crushers break medium and above medium rocks and ores in the first or secondary crushing process. It is popular in mining, metallurgy, construction, infrastructure, transportation, and the chemical industry.

As one of the best cone crusher manufacturers, we offer a range of cone crusher types. These include single cylinder hydraulic cone crushers, multi cylinder hydraulic cone crushers, spring cone crushers, and more.

- Feeding size (mm): 13~560

- Opening range(mm):3~60

- Capacity (tons/hour): 40~1500