Jaw Crusher For Sale

A jaw crusher is crushing equipment in the first or secondary crushing process. The jaw crusher breaks down large rocks, ores, and other materials into smaller particles.

As one of the professional jaw crusher manufacturers, we are dedicated to designing, manufacturing, and supplying high-quality jaw crusher machines.

We mainly provide JC and PE jaw crushers for sale. They are popular in mining, metallurgy, construction, infrastructure, transportation, and the chemical industry.

- Feeding size (mm): 120-1250

- Opening range(mm):10-650

- Capacity (tons/hour): 2-1590

Jaw crusher applications and Applicable materials

Jaw crushers have a wide range of applications in industries such as aggregate, mining, grinding, construction, highways, metallurgy, and cement. They are used for crushing and processing various materials including quartz stone, bluestone, river pebble, cobblestone, limestone, iron ore, aggregate, etc.

- In mining, jaw crushers are utilized for extracting valuable metal ores.

- In construction, they are used for producing aggregates and building materials.

- In highway construction, they are used for producing road base and pavement materials.

- Additionally, jaw crushers are employed in waste recycling and reutilization processes, providing crushing solutions for discarded construction materials, furniture, electronic equipment, and more.

How does a jaw crusher work?

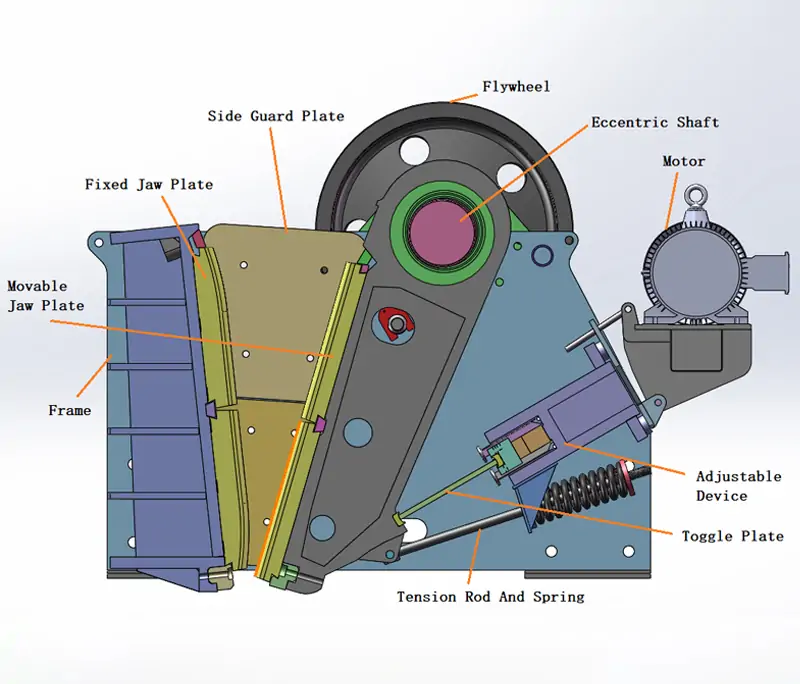

The working principle of jaw crusher

A jaw crusher uses a pair of jaws, one fixed and the other moving, to move back and forth against each other. The movable jaw exerts a force on the rock or material being crushed, pressing it against the fixed jaw.

The crushing begins when the feed material is loaded into the feed hopper and fed into the crushing chamber. The eccentric rotating drive shaft causes the movable jaw to oscillate or move back and forth, generating the crushing action.

The material is gradually crushed between the two jaws as it enters the crushing chamber. The compressive force applied by the jaws breaks the material into smaller pieces. The size of the crushed material is determined by the gap between the jaws, which can be adjusted to control the desired output size.

The crushed material is discharged through the discharge opening at the bottom of the crusher. The size of the discharge opening can also be adjusted to control the final product size.

Jaw Crusher Specification

Technical Data of JC Jaw Crusher:

| Type | Feeding opening size(mm) | Max. feeding size(mm) |

Discharge range opening(mm) | Capacity(t/h) | Eccentric shaft speed(r/min) | Power(kw) | Weight(t) | Dimesion(L*W*H)(mm) |

| C96 | 580*930 | 460 | 60-175 | 120-455 | 300 | 90 | 11.87 | 2880*1755*1460 |

| C100 | 760*1000 | 640 | 70-200 | 150-545 | 260 | 110 | 23.3 | 3670*2420*2490 |

| C106 | 700*1060 | 580 | 70-200 | 155-580 | 280 | 110 | 17.05 | 3320*2030*2005 |

| C110 | 850*1100 | 730 | 70-200 | 190-625 | 230 | 160 | 29.5 | 3770*2385*2750 |

| C116 | 800*1150 | 680 | 70-200 | 170-600 | 260 | 132 | 21.5 | 3600*2400*2730 |

| C125 | 950*1250 | 800 | 100-250 | 290-845 | 220 | 160 | 43.91 | 4100*3010*3140 |

| C140 | 1070*1400 | 920 | 125-250 | 385-945 | 220 | 200 | 54.01 | 4400*3010*3140 |

| C145 | 1100*1400 | 950 | 125-275 | 400-1070 | 220 | 200 | 63.19 | 4600*3110*3410 |

| C160 | 1200*1600 | 1020 | 150-300 | 520-1275 | 220 | 250 | 83.3 | 5900*3700*4280 |

| C200 | 1500*2000 | 1200 | 175-300 | 760-1590 | 220 | 400 | 137.16 | 6700*4040*4465 |

Technical Data of PEX/PE Jaw Crusher:

| Type&Specification | Max. feeding size(mm) |

Discharge range opening(mm) | Capacity(t/h) | Power(kw) | Weight(t) | Dimesion(L*W*H)(mm) |

| ZG-PE-150*250 | 125 | 10-40 | 2-6 | 5.5 | 1 | 900*750*950 |

| ZG-PE-250*400 | 210 | 20-60 | 8-16 | 15 | 3 | 1450*1280*1300 |

| ZG-PE-400*600 | 350 | 40-100 | 20-40 | 30 | 6 | 1700*1700*1650 |

| ZG-PE-500*750 | 400 | 50-120 | 30-80 | 45 | 11 | 2000*1950*1900 |

| ZG-PE-600(A)*900 | 425 | 60-130 | 45-95 | 55 | 12.5 | 2200*1960*1950 |

| ZG-PE-600*900 | 480 | 75-200 | 80-200 | 75 | 18 | 2400*2230*2400 |

| ZG-PE-700*1000 | 550 | 80-210 | 90-240 | 75 | 19.5 | 2400*2280*2400 |

| ZG-PE-750*1060 | 630 | 80-235 | 120-300 | 90 | 26 | 2500*2370*2780 |

| ZG-PE-900*1200 | 750 | 95-265 | 280-500 | 110 | 45 | 3200*2820*3260 |

| ZG-PE-1100*1400 | 900 | 120-260 | 350-750 | 200 | 75 | 3850*3050*4000 |

| ZG-PE-1200*1500 | 1020 | 150-300 | 700-950 | 250 | 85 | 4050*3150*4200 |

| ZG-PE-1300*1600 | 1200 | 220-550 | 800-1200 | 355 | 122 | 5100*4700*4300 |

| ZG-PE-1500*1800 | 1250 | 280-650 | 1000-1400 | 500 | 169 | 5600*5020*4950 |

| ZG-PEX-150*750 | 120 | 10-40 | 8-25 | 15 | 3.1 | 1320*1570*1050 |

| ZG-PEX-150*1000 | 140 | 15-45 | 12-35 | 22 | 5 | 1400*1810*1250 |

| ZG-PEX-200*1000 | 160 | 15-50 | 12-40 | 22 | 5 | 1530*1810*1250 |

| ZG-PEX-250*750 | 210 | 20-60 | 15-40 | 30 | 5.5 | 1480*1710*1470 |

| ZG-PEX-250*1000 | 210 | 20-60 | 20-50 | 30 | 6.5 | 1530*1920*1380 |

| ZG-PEX-350*750 | 300 | 20-60 | 30-80 | 30 | 7.5 | 1650*1850*1640 |

| ZG-PEX-200*1200 | 200 | 20-60 | 30-100 | 37 | 8.5 | 1650*2150*1460 |

| ZG-PEX-250*1200 | 210 | 20-60 | 40-120 | 45 | 8.5 | 1650*2150*1460 |

| ZG-PEX-300*1300 | 250 | 20-90 | 60-180 | 55 | 11 | 1870*2400*1730 |

| ZG-PEX-350*1500 | 300 | 20-90 | 80-220 | 75 | 15 | 1900*2660*1830 |

| ZG-PEX-600*1500 | 550 | 45-120 | 120-260 | 90 | 22 | 2200*2750*2200 |