Aggregate industry

Aggregate Crushing production line

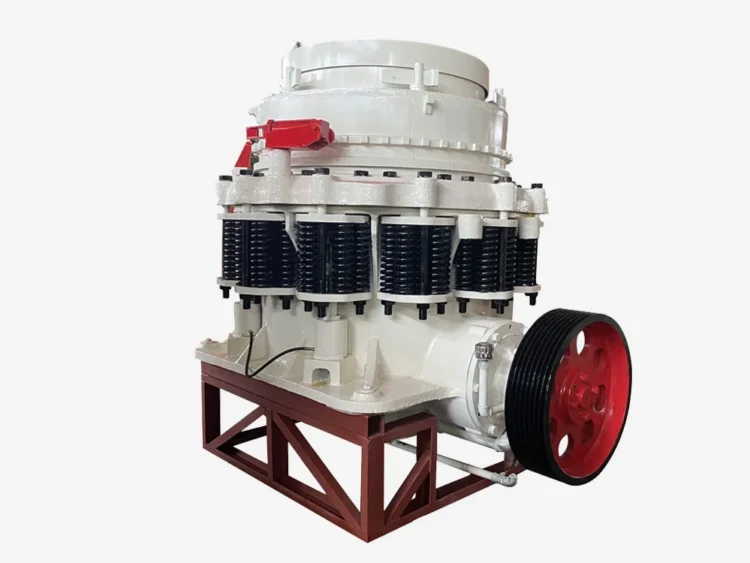

The line is composed of a vibrating feeder, jaw crusher, cone crusher, impact crusher, hammer stone crusher, vibrating screen, belt conveyor, electric control panel, and dust removal equipment. We use jaw crushers for primary/coarse crushing. Cone crushers are for secondary crushing. The next is hammer crushers and impact crushers for fine crushing. The vibrating feeder and screens are auxiliary equipments.

The crushed stone production line is widely used in limestone, granite, marble, basalt, gravel, aggregate, quartz, cobblestone, dolomite, calcite, and other stone materials.

Limestone

Granite

Gangue

Basalt

Barite

Dolomite

Pebble

Calcite

Related equipments

success cases

Limestone

For the limestone aggregate production line, we choose a 6013-rod feeder, a 912-jaw crusher, 2 sets of 1520 impact crushers, and 2 sets of 2460-4 layer vibrating screens for the screening. We add a transfer bin between the jaw crusher and the impact crusher. It is to ensure the continuity of subsequent feeding. This production line can guarantee an output of 400-500 tons per hour. If the customer has a demand for sand-making, we can add sand-making equipment after the impact crusher.

aggregate production process

Each material processing equipment has its particular function. We make them play the best role in the material processing plant. It is convenient for customers to select and determine the appropriate equipment according to the special material processing field.

Stage 1: feeding

The material is evenly fed through the silo by the vibrating feeder.

Stage 2: crushing

The jaw crusher performs coarse crushing.Then the coarsely crushed materials are transported to the impact crusher through the belt conveyor.

Stage 3: secondary and tertiary crushing

We use impact crusher to do secondary and tertiary crushing to get the required size.

.

Stage 4: screening

The circular vibrating screen is used to screen the materials well.