Introduction:

How does a cone crusher work? It is a query you would ask after locating a cone crusher working at a site. It belongs to the heavy machinery category that can easily break large to medium feed material into smaller particles. However, the principal operation will blow your mind off! So, this blog encompasses the working principle involved in cone crusher machinery.

How Does A Cone Crusher Work- the basic working principle

Before jumping to its working technology, you shall first understand what a cone crusher is. Understanding the cone crusher working principle is essential to have a better know-how about it.

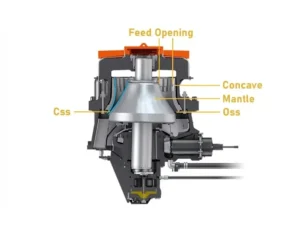

By looking at its name, you might think it is a cone-shaped crusher; however, you’re mistaken. It has more like a concave shape. In general, the machine consists of two parts. One still part remains stationary when the machine operates, while others move in motion. Place the material you want to crush in the crusher’s feed chamber. Then, when both parts of the crusher are intact, it will begin crushing. The moving and stationary parts both work in a synchronized motion. This motion results in generating fine particles from the large feeding material.

These cone crushers serve a significant number of industries. Hence, their usage makes them ideal machinery for people to use at construction sites, cement plants, and even mining. The reason why people select it for crushing is that it can break sturdy and rigid material efficiently.

Following are some parts that get discussed in the blog.

- Feeding (crushing) chamber

- Concave

- Mantle

- Shaft (main)

- OSS and CSS

- Electrical motor

- Eccentric bushes

- Chamber outlet

- Automated control system

How does a cone rock crusher work?

How does a cone rock crusher work? Let’s start with it.

1. Feeding in the material to crush

How does a cone crusher work? The process starts when you connect a conveyor belt to the crusher. A conveyor belt carries the large stones or other pieces directly into the feed chamber of the crusher. You can quickly locate the feeding chamber mounted above the cone crusher. The feed material then passes down to the main body of the crusher through the distribution plates. These plates help to perform even spread of the feed and prevent accumulation of feed to one side.

2. A sleeve called concave

The concave is present next to the mantle of the crusher. Manufacturers design it with a steel body. The overall shape of this part is just like a concave shape that bends inwards. Whenever the material passes through the crusher, it gets severe hitting by the concave. Hence, it eventually breaks the large pieces into smaller ones.

3. Mantle for oscillation

A mantle is a part of the crusher that you can locate at the head of the crusher. Similarly, the mantle attaches to a shaft. When the oscillation begins, it allows eccentric motion to happen. However, remember that the mantle won’t complete an entire rotating cycle. The mantle starts targeting the feed material as soon as the rotation begins. An electrical motor is there to drive the mantle.

Along the mantle, you can find a concave. Now consider this step properly. The mantle behaves as a motion part, whereas a concave is a stationary plate-like structure. When it begins oscillating, the feed gets shit with the inactive concave plates in different directions. This phenomenon allows the material to break down into smaller, more manageable pieces quickly. Hence, when the gap between these two sides is minimal, it allows for better feed grinding.

4. OSS and CSS

There are two sides to the mantle, one is OSS, and the other is CSS. OSS refers to the open side setting, and the CSS refers to as closed side setting. A user must adjust the two sides setting to crush the material. Then, the CSS side setting will allow large particles to go down. In comparison, the OSS side setting allows smaller particles to pass through.

5. The electrical motor

How does a cone crusher work? The principle is that it operates on an electrical motor. Thus, the motor aids the crushing process. The motor helps to run the mantle of the crusher. Also, it drives the mantle with great power.

6. Eccentric bushing

At the bottom end of the shaft, you will find the eccentric bushes. The bushes are encapsulated by carbon and bronze-made sleeves. Hence, it controls the throw of the variable sizes of the sleeves.

7. The outlet of the crusher

How does a cone rock crusher work come to an end now? The crushed stones or any other material is released through the chamber outlet. Note that the size of this opening primarily indicates the size of the final product exiting the chamber. Then, you can attach another conveyor to move the crushed pieces to the destination required.

8. Automated control system

The entire cone crusher working principle happens slowly. There are different sensors, indicators connected to the crushers. All these sensors help you excellently operate the machinery. The sensors sense the load, the crushing size, etc. Hence, it improves the efficiency and ability of the crushers to work.

Some tips for operating the cone crushers professionally

How does a cone crusher work? The working mechanism is thoroughly explained above. So, you can learn some tips for handling the crushers.

-

Understand the ability to crush the machine

Every cone crusher comes with specific limitations in its designs. However, you must stay within the capacity, speed, or productivity as high as it is designed to do.

-

Maintain a consistent material feeding level

Follow this tip if you want the output material’s specific size, density, or volume. You shall set a particular level for feeding in the material. Sometimes, you might use the controller set to implement this tip. Then only you will be able to achieve uniformity in the sizes of output feed.

-

Place the feed in the center of the feeding chamber

When installing a conveyor belt to the feeding area of the crusher, make sure you place it in the center. When the feed enters through the center, it is more likely to get an even distribution. Thus, it directs the crusher’s actions toward the inserted material.

Conclusion:

How does a cone crusher work? The working mechanism is quite simple and easy to understand. Hence, you can go through the parts of crushers and their function to get complete know-how about them.