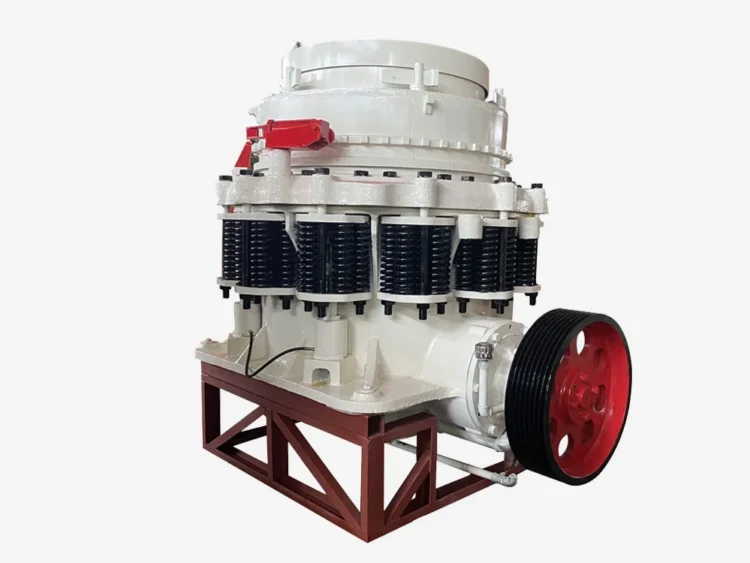

Advantages Of JC Type Jaw Crusher

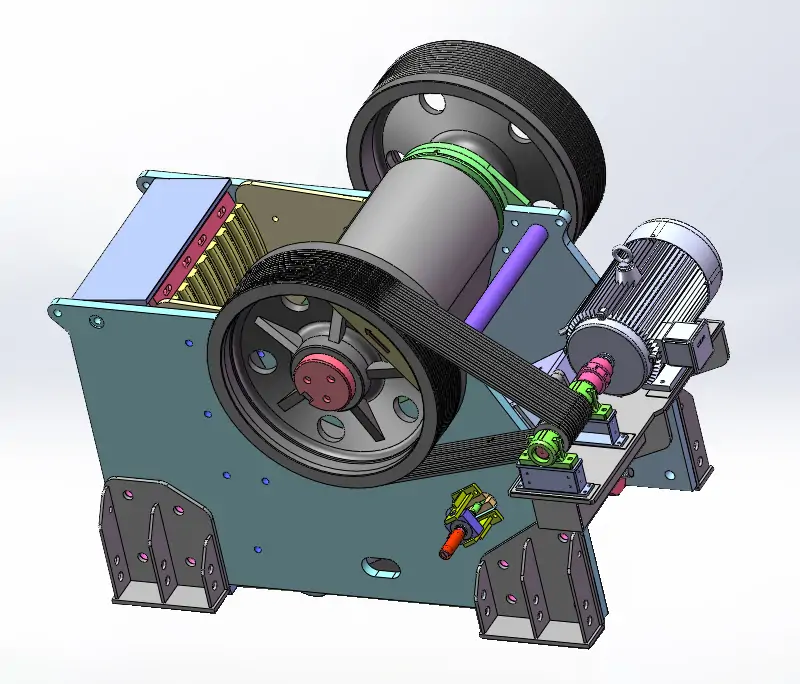

JC type jaw crusher belongs to coarse crushing equipment in the mining industry. It plays a vital role in the production line, which can crush hard materials such as quartz stone, bluestone, river pebble, cobblestone, limestone, iron ore, and other stone processing crushing. Because of its reliable work, simple operation, easy maintenance, and other advantages, the majority of the mining industry is welcome.

1. High output, big crushing ratio, low energy consumption, large feeding size

2. High impact resistance movable jaw assembly

3. Without installation of anchor bolts, integrated steel frame base

4. Strong body structure, oversized bearing design

Application areas: mining, smelting, construction, highway, railroad, water conservancy, chemical industry, and many other industries.

Prices Of JC Type Jaw Crusher

JC Jaw Crusher prices are different depend on different crusher models. As the leading mining crusher manufacturer with almost 30 year history in China, we will provide maximum preferential price and discount for you. Welcome to visit our company and factory.

What is the working principle of jaw crusher?

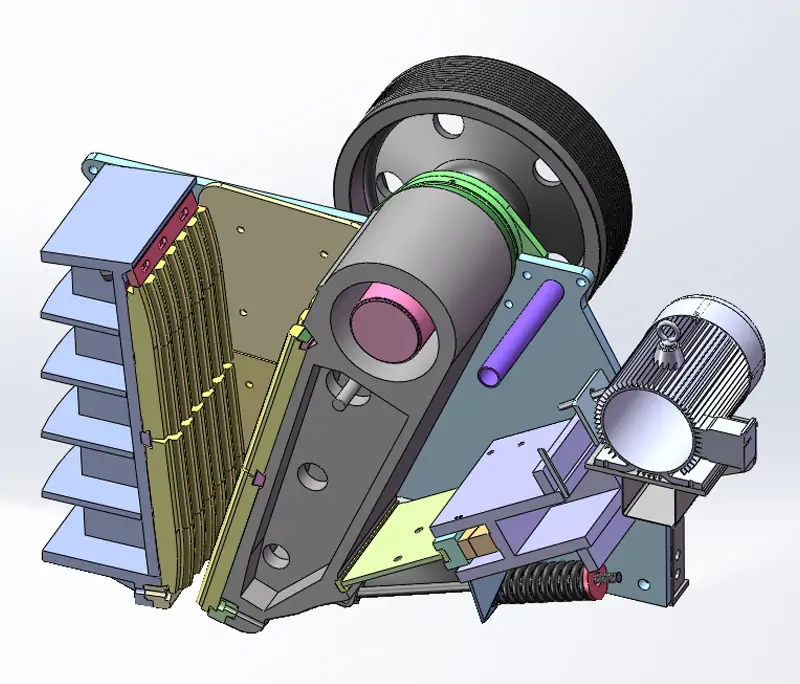

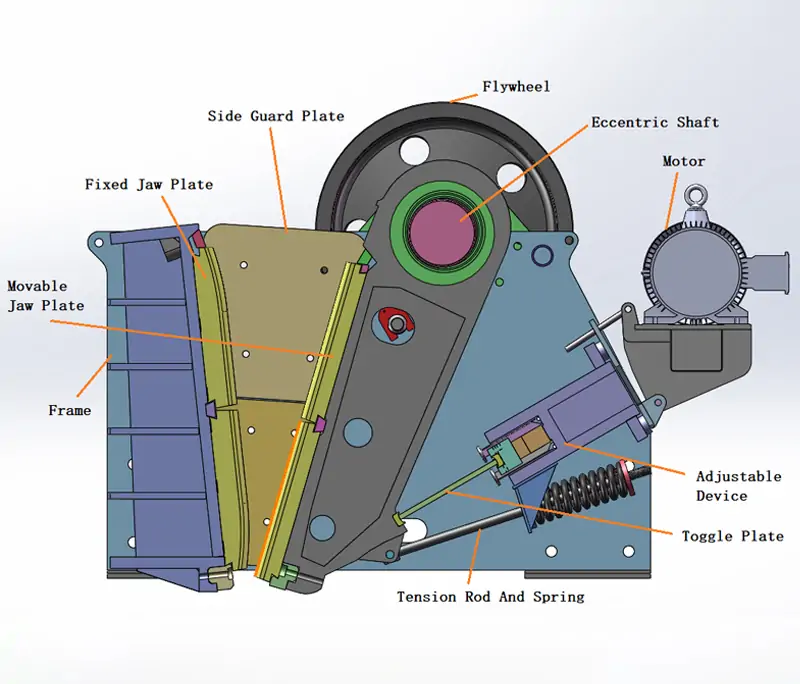

The jaw crusher crushing method is a curved extrusion type, and the operation principle is to simulate the movement of two jaws of animals. When the jaw rises, the angle between the elbow plate and the jaw becomes larger, thus pushing the jaw plate closer to the fixed jaw plate, and the material is crushed by the extrusion, rubbing and grinding between the two jaw plates; when the jaw goes down, the angle between the elbow plate and the jaw becomes smaller, and the jaw plate leaves the fixed jaw plate under the action of the tie rod, and spring and the crushed material is discharged freely by gravity. The crushed material is discharged freely through the discharge port in the lower part of the jaw cavity under the action of gravity. With the continuous rotation of the motor, the jaw crushes and discharges the material periodically to realize mass production.

The JC series European jaw crusher is a new-generation product based on the experience of traditional jaw crusher design and manufacture and successfully developed by the finite element analysis method. Compared with traditional jaw crushers, JC series jaw crushers pay more attention to details in design and manufacturing. Adopting high-strength materials and manufacturing processes has the advantages of higher structural strength, higher equipment reliability, a larger crushing ratio, higher output, and lower overall cost.

Technical Advantages of JC Jaw Crusher

Sturdy structure:

The frame is divided into welded type and assembled type: welded type for small and medium sizes, assembled type for large sizes.

Superior cavity design:

Symmetrical “V” shaped cavity design, the large inclination of elbow plate, large stroke, reasonable speed, resulting in larger feed size, higher output, more uniform size, and lower jaw wear.

The heavy-duty jaw assembly is durable:

The heavy-duty jaw assembly adopts a forged heavy-duty eccentric shaft, heavy-duty rolling bearings, and finite element software optimized jaw body to ensure the impact resistance and high stability of the jaw assembly; the labyrinth seal and centralized lubrication system ensure that the bearing grease is not polluted and the lubrication is more convenient, which makes it run longer and more stable.

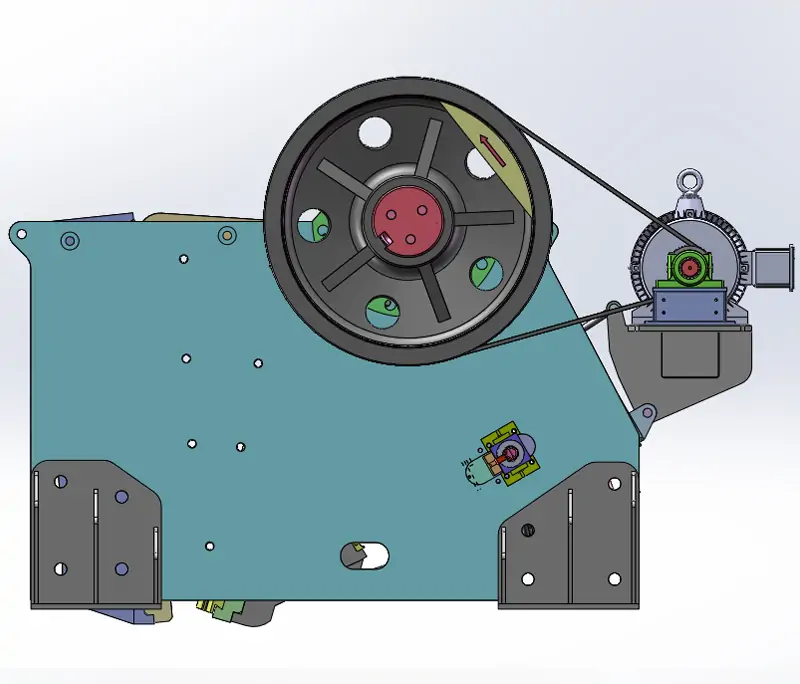

Integrated motor installation:

The integrated installation method of motor block and crusher frame not only saves the installation space of the jaw crusher and reduces the length of the v-belt but also enables the adjustment of the v-belt tension due to the synchronous movement of the frame, motor block and motor, and the adjustable motor block, which results in a longer service life of the v-belt.

Integral bearing housing:

The integral cast steel bearing housing structure ensures that it fits with the frame, avoiding unnecessary radial load on the bearing during the fastening process of the combined bearing housing, making the bearing run more smoothly.

Convenient and quick size adjustment:

JC jaw crusher adopts a mechanical or hydraulic discharge opening adjustment device, whose double wedge adjustment method is simpler, safer, and quicker than the corresponding shim adjustment operation, saving downtime.

Moving jaw guard design:

Heavy-duty guard plate is installed above the moving jaw to avoid the impact of materials and effectively protect the moving jaw body and its internal bearings from damage.

Vibration damping installation design:

The crusher is fixed with a special rubber damping device, which effectively absorbs the peak vibration of the equipment while allowing the crusher to be displaced in both vertical and longitudinal directions, thus reducing the impact on the foundation.

Technical Data Of JC Type Jaw Crusher

| Type | Feeding opening size(mm) | Max. feeding size(mm) |

Discharge range opening(mm) | Capacity(t/h) | Eccentric shaft speed(r/min) | Power(kw) | Weight(t) | Dimesion(L*W*H)(mm) |

| C96 | 580*930 | 460 | 60-175 | 120-455 | 300 | 90 | 11.87 | 2880*1755*1460 |

| C100 | 760*1000 | 640 | 70-200 | 150-545 | 260 | 110 | 23.3 | 3670*2420*2490 |

| C106 | 700*1060 | 580 | 70-200 | 155-580 | 280 | 110 | 17.05 | 3320*2030*2005 |

| C110 | 850*1100 | 730 | 70-200 | 190-625 | 230 | 160 | 29.5 | 3770*2385*2750 |

| C116 | 800*1150 | 680 | 70-200 | 170-600 | 260 | 132 | 21.5 | 3600*2400*2730 |

| C125 | 950*1250 | 800 | 100-250 | 290-845 | 220 | 160 | 43.91 | 4100*3010*3140 |

| C140 | 1070*1400 | 920 | 125-250 | 385-945 | 220 | 200 | 54.01 | 4400*3010*3140 |

| C145 | 1100*1400 | 950 | 125-275 | 400-1070 | 220 | 200 | 63.19 | 4600*3110*3410 |

| C160 | 1200*1600 | 1020 | 150-300 | 520-1275 | 220 | 250 | 83.3 | 5900*3700*4280 |

| C200 | 1500*2000 | 1200 | 175-300 | 760-1590 | 220 | 400 | 137.16 | 6700*4040*4465 |