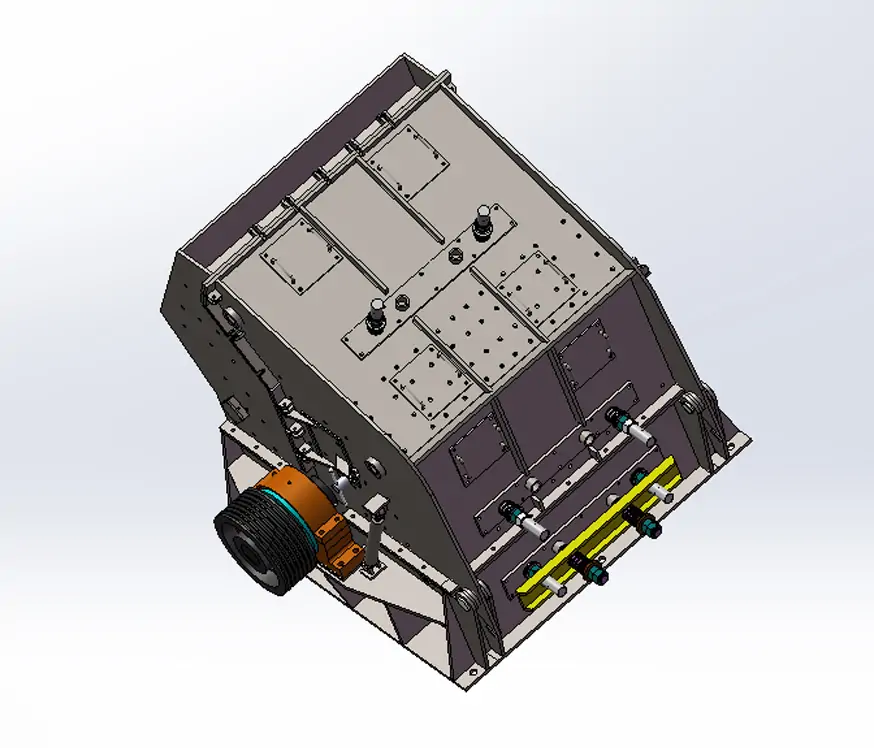

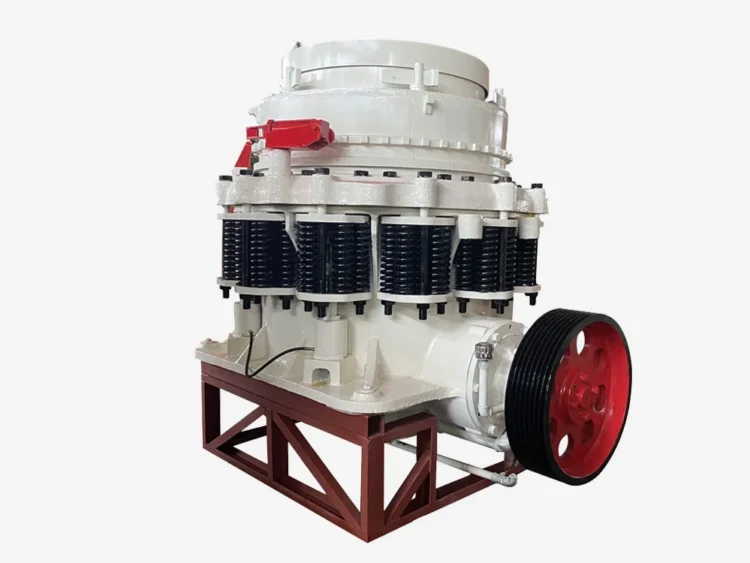

Product Introduction of PF Impact Crusher

PF Impact Crusher is a new type of impact crusher designed by BANGDE. It is popular in minerals, highways, energy, cement, and other industries.

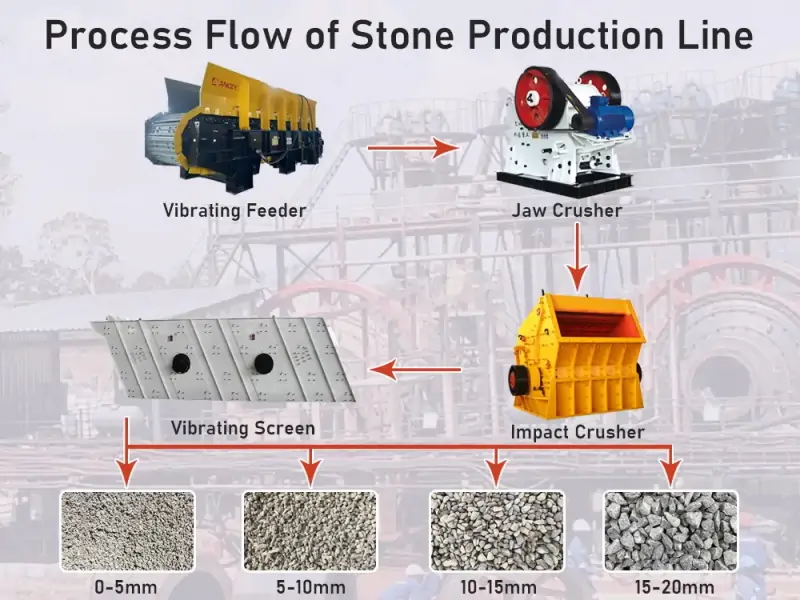

Impact crusher is named according to the working principle. It uses the principle of impact crushing to crush the materials. It is a finer crusher machine than a jaw crusher and is mainly used in the stone production line for fine-crushing operations. It often cooperates with jaw crushers for crushing.

Impact crusher is mainly used in metallurgy, the chemical industry, building materials, the hydropower industry, and other materials processing where relocation operations are often required. It is especially used for the operation of highways, railroads, hydropower projects, and other liquid stone materials. Various configurations can be used for it according to the type and scale of processing raw materials and different requirements of finished materials. It is commonly used to crush limestone, granite, concrete, and other materials with relatively low hardness.

Advantages of PF Impact Crusher

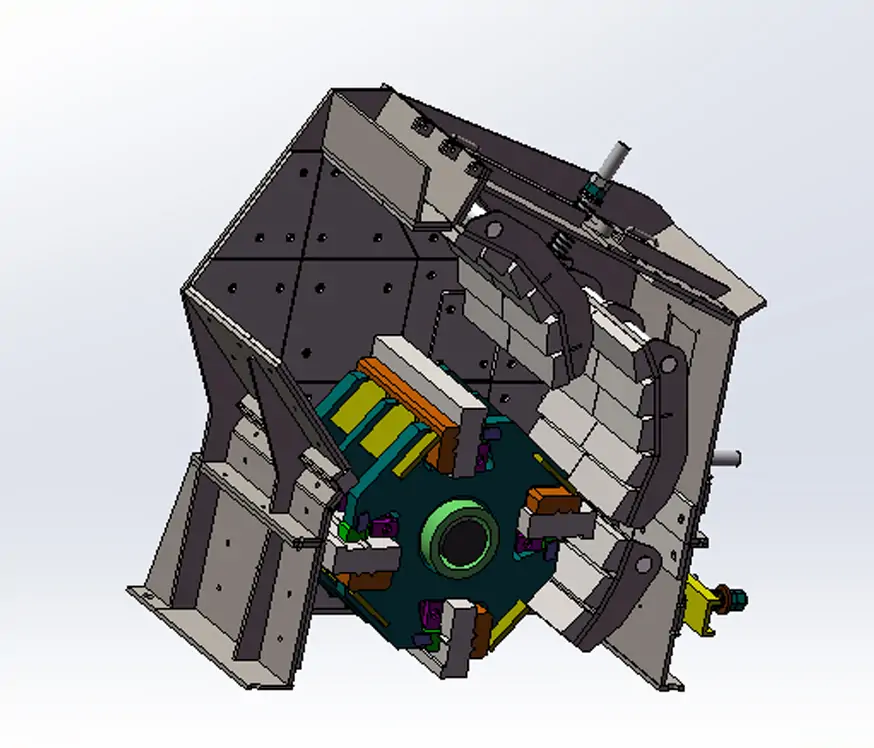

The impact crusher can handle materials with side lengths of 100-500 mm or less, and the compressive strength can reach up to 350 MPa. It has the advantages of a large crushing ratio and cubic particles after crushing. Its discharge size can be adjusted, and the crushing specifications are diversified.

1. High efficiency and energy saving

2. Unique structure

3. Adjustable discharge size, uniformed granularity

4. Higher integrated benefits

Application areas: building materials, ore crushing, railroad, highway, energy, transportation, energy, cement, mining, chemical and other industries.

Prices of PF Impact Crusher

PF Impact Crusher prices are different depend on different crusher models. As the leading mining crusher manufacturer with almost 30 year history in China, we will provide maximum preferential price and discount for you. Welcome to visit our company and factory.

Technical Advantages of PF Impact Crusher

The PF impact crusher has the following five advantages in the process of crushing.

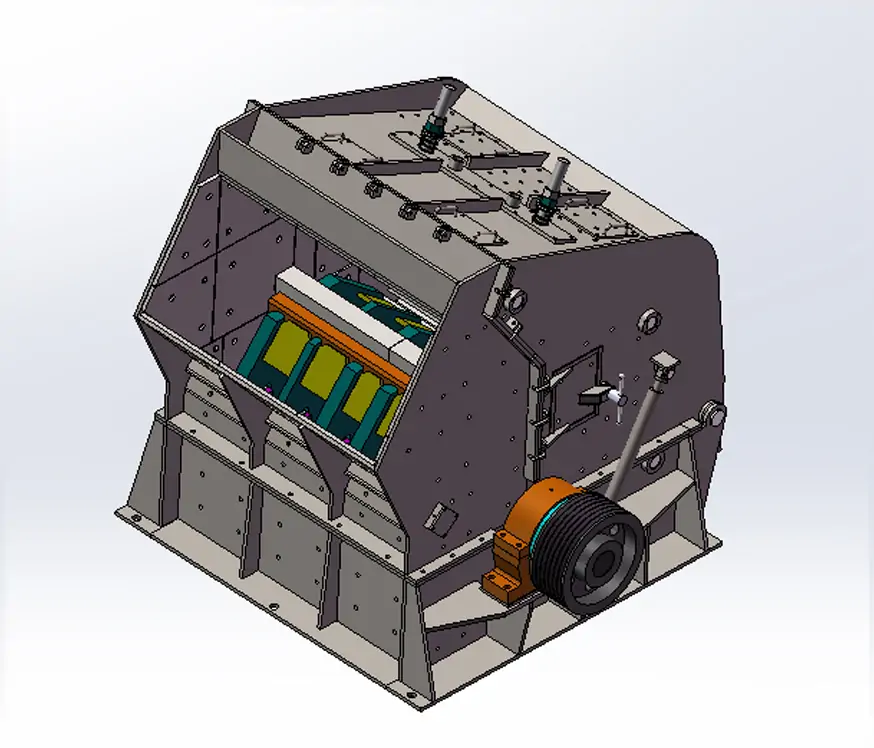

1. More effective handling of materials with large wet volumes and effective prevention of material blockage

When handling materials with excessive moisture content, the impact crusher’s feed chute and impact plate can be equipped with a heating device. This prevents the material from sticking. The impact crusher can effectively prevent clogging without needing a bottom screen.

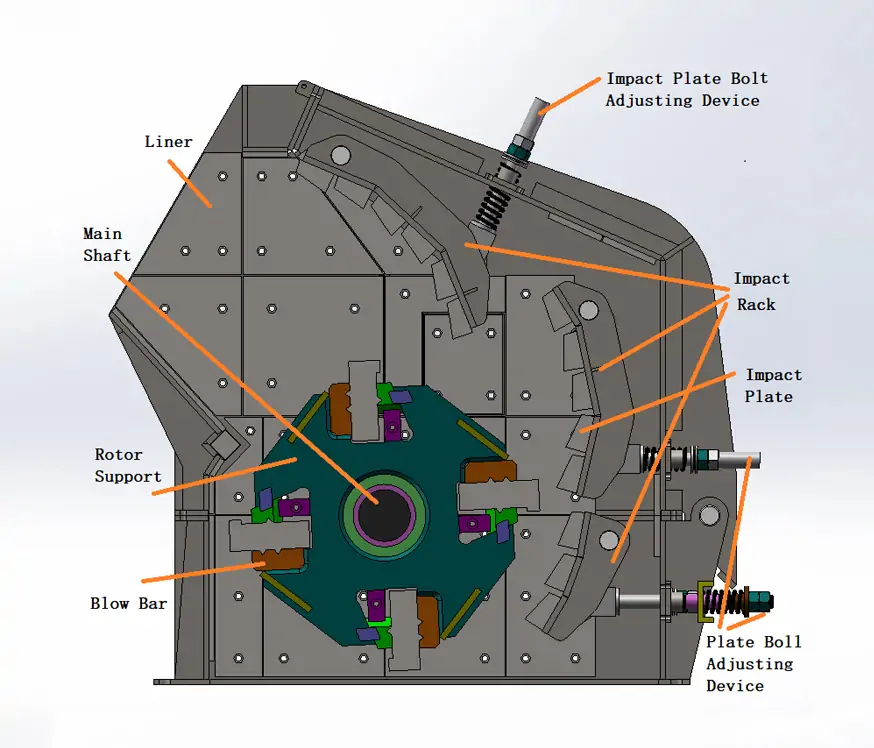

2. Suitable for crushing a wide range of material hardness

The hammer of the impact crusher is firmly fixed on the rotor by a mechanical clamping structure. When rotating with the rotor, it has large rotational inertia. Compared with a hammer crusher (the hammerhead is hanging), the rotor of an impact crusher has more momentum, which is suitable for crushing harder materials. At the same time, the energy consumption is lower.

3. It is easy and flexible to adjust the size of the discharge, and the adjustment range is wide

The impact crusher can adjust the discharge size in many ways, such as adjusting the rotor speed, adjusting the gap between the impact plate and the grinding chamber, etc. The gap adjustment can be made mechanically or hydraulically. The hydraulic adjustment system can be easily adjusted by the local operation button or the remote control system.

4. Low wear of wearing parts and high metal utilization rate

The wear of the impact crusher plate hammer only occurs on the side facing the material. When the rotor speed is normal, the feed material will fall on the surface of the plate hammer (striking surface). The back and sides of the plate hammer are not worn. Even on the side facing the material, wear is minimal. Also, the bottom grinding bar is easily replaced. The metal utilization rate of an impact crusher plate hammer can be as high as 45%-48%.

5. Easy replacement of spare parts and reduced maintenance costs

Only six plate hammers are installed on the rotor of the impact crusher, which can be easily replaced with the designed special tools. It only takes one shift to replace one set of plate hammers.

Technical Data of PF Impact Crusher

| Type | Max. feeding size(mm) | Capscity(t/h) | Power(kw) | Weight(t) | Rotor diameter(mm) | Potor length(mm) |

| PF-0504 | 100 | 5-8 | 7.5 | 1.5 | ф500 | 400 |

| PF-0607 | 120 | 10-20 | 30 | 4.1 | ф640 | 700 |

| PF-1007 | 250 | 15-30 | 37 | 6.5 | ф1000 | 700 |

| PF-1010 | 250 | 30-80 | 75 | 12.7 | ф1000 | 1000 |

| PF-1210 | 300 | 60-120 | 110 | 13.5 | ф1250 | 1050 |

| PF-1212 | 300 | 80-140 | 132 | 14.8 | ф1250 | 1250 |

| PF-1214 | 300 | 100-160 | 132 | 16.8 | ф1250 | 1400 |

| PF-1310 | 300 | 70-140 | 132 | 14.2 | ф1300 | 1050 |

| PF-1315 | 300 | 100-180 | 185 | 21.5 | ф1300 | 1500 |

| PF-1320 | 300 | 150-250 | 200 | 24.5 | ф1300 | 2000 |

| PF-1520 | 300 | 180-320 | 220 | 29.5 | ф1500 | 2000 |

| PF-1622 | 350 | 400-600 | 250 | 101 | ф1600 | 2200 |

| PF-1822 | 400 | 500-800 | 280 | 118 | ф1800 | 2200 |