Introduction:

The jaw crusher is the first choice of coarse crushing equipment. Many customers know a lot about jaw crushers but are still unfamiliar with how to install and use them properly. This article will explain in detail the installation and use of the jaw crusher.

What is the jaw crusher for?

The jaw crusher belongs to primary and secondary crushing equipment in the mining industry and plays a vital role in the production line. It can crush hard materials, such as quartz stone, pebbles, limestone, iron ore, and so on. It is welcomed by the mining industry for its high output, simple operation, easy maintenance, etc.

How To Install And Use Jaw Crusher Properly?

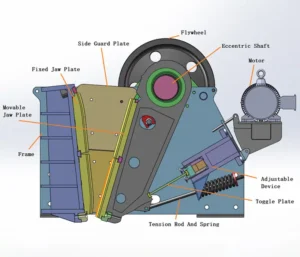

A jaw crusher is mainly composed of a frame, fixed jaw plate, movable jaw plate, side guard plate, adjusting seat, toggle plate, etc. As we can see from the jaw crusher diagram below, the structure of the jaw stone crusher is complex. Therefore, users must read the installation instructions and accept the guidance of professional technicians when installing and using the device.

1. Installation Instructions

Users should check the jaw crusher machine when they receive it in order to eliminate any damage that may occur during transportation.

a. This jaw stone crusher vibrates a lot when it works. Therefore, to reduce vibration and noise, it is recommended to install this machine on a concrete foundation so that the vibration generated by the machine when working will not affect the foundation of the building. It is better to pad the middle of the crusher and the concrete foundation with hardwood matting, rubber bands, or other vibration-damping materials.

b. The weight of the foundation should be roughly 5-10 times the machine’s weight. The depth of the foundation should be greater than the depth of the land frozen at that place.

c. The tensioning spring should be loosened before adjusting the discharge opening. After it is adjusted, adjust the spring’s tension appropriately to prevent the toggle plate from falling off when working.

2. Instructions For Use

Preparation before starting:

- The lubrication of the bearing should be carefully checked. Also, check whether the grease at the connection between the bearing and the toggle plate is sufficient.

- Check carefully whether all the tightening solids are completely tightened.

- Check carefully whether the transmission belt is good. The belt is found to be damaged and should be replaced in time. When the belt or pulley has oil, apply a clean cloth to wipe it clean.

- Check the condition of the protection device. If it is not safe, deal with it immediately.

- Check the condition inside the crushing chamber. Remove any ore or other debris immediately.

Crusher working:

- Check that the machine and transmission parts are in normal condition before starting.

- The jaw crusher should be started under no load.

- After starting, if abnormal conditions are found, the machine should be stopped immediately. The crusher should be started again only after the abnormal condition is identified and eliminated.

Maintenance and use:

- After the normal operation of the crusher, start feeding.

- Add the materials evenly into the crushing chamber, and side feeding should be avoided to prevent sudden changes of load or sudden increases on one side.

- The maximum temperature of the bearing under normal conditions should not be higher than 70 degrees. If the temperature rises above 70 degrees, you should stop immediately and find out what is causing it.

- Stop adding material before stopping. The motor can be switched off after the material has been completely emptied from the crushing chamber.

- When using, if the material blocks the crushing chamber, the motor should be shut down immediately. The material must be eliminated before starting again.

- After the jaw plate is worn out, it can be turned around and used.

Lubrication:

- Regular attention and timely lubrication can ensure normal operation and long service life.

- The grease used in this machine should be decided according to the machine’s location, temperature, and other conditions. Generally can use calcium-based, sodium-based, or calcium-sodium grease.

- Add grease to the bearing seat. The amount to be added is approximately 50-70% of the volume of the bearing housing. The grease should be changed every three months. When changing, please use clean gasoline or kerosene to clean the running edge of the roller bearing carefully.

- The place where the toggle plate and toggle plate pad are in contact must be injected with grease before the machine starts.

Conclusion:

The above briefly describes the correct installation and use of a jaw crusher. Installing a jaw crusher machine needs to be implemented according to the equipment type. The foundation drawing required is different for different equipment and installation methods.

As one of the professional jaw crusher manufacturers, we can provide jaw stone crushers with high crushing efficiency. In addition, we can also customize for customers according to requirements and provide perfect pre-sale, in-sale, and after-sale services to provide technical support and services for customers. Our engineers can go to the equipment site for service at the customers’ request. If you have any demand, please feel free to contact us.