Introduction:

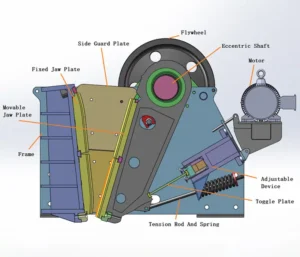

The jaw crusher is the first choice for primary crushing in the crushing production line. Whether it is the aggregate production line or the sand production line, jaw stone crushers are inseparable.

Due to high production capacity, smooth operation, and good crushing performance, jaw crusher machines are widely used in mining crushing work. However, in the actual production process, with the continuous operation of the equipment, wear-resistant parts are constantly consumed. To ensure good production capacity, the discharge size needs to be adjusted regularly. This can meet the feed requirements of medium and fine crushing equipment and guarantee the product size and capacity remain unchanged. The discharge opening is adjusted to meet the customer’s use requirements and achieve a good crushing effect.

Why is it necessary to adjust the discharge size of a jaw crusher?

The jaw stone crushers with good crushing performance are widely used in mining crushing work. However, during the continuous crushing process, as the operating time of the equipment increases, the tooth plate of the jaw crusher will wear out, and the size of the discharge opening will gradually become larger. This results in a gradual thickening of the size of the crushed product. In order to meet the feed requirements of the medium and fine crushing plant, the product size needs to remain constant, so the discharge opening must be adjusted to achieve the desired crushing effect.

How to adjust the discharge size of the jaw crusher?

Generally there are two ways to adjust the discharge opening of the jaw crusher machine:

1. Gasket adjustment

The adjusting gaskets are generally located behind the adjusting seat. When you need to adjust the discharge opening, you can increase or decrease the number of gaskets and change the total thickness. So the front and rear position of the toggle plate changes, and move the front and rear position of the lower part of the moving jaw to realize the size of the discharge opening change.

-

Inserting the gaskets from the back of the jaw stone crusher

The adjusting gaskets are inserted from the rear of the crusher. The gasket is shorter in length and lighter in weight. The operator’s operating space is limited, and it is not very convenient to change the gaskets.

-

Inserting the gaskets from the side of the jaw crusher

The adjusting gaskets are inserted from the side plate of the crusher, which is longer and heavier. The operator’s operating position is better and safer.

The gasket adjustment is relatively simple. However, it is often inconvenient. Adjusting the discharge opening by adding or removing the gaskets is difficult. It needs to be placed close to the crusher, which takes up space. On the other hand, this has to prevent loss. It cannot be adjusted steplessly and cannot be adjusted automatically by hydraulic means.

2. Wedge adjustment

The wedge adjustment device mainly consists of two identical wedges. The wedges are located behind the toggle plate in the adjusting seat, and the bevels of the two wedges fit together relatively. By changing the relative positions of the two wedges, the total thickness of the wedges can be changed. So the front and rear position of the toggle plate changes, and move the front and rear position of the lower part of the moving jaw to realize the size of the discharge opening change.

-

Mechanical adjustment

Mechanical adjustment means that the movement of the wedge is achieved by manually turning the adjusting screw. The adjusting screw is located on both sides of the crusher. One end of the adjusting screw is connected to the wedge, and it is mounted on both sides of the side plate of the crusher frame by the adjusting screw and the support. When the discharge opening needs to be adjusted, the screw is turned with a wrench on both frame sides. This can pull the wedge, change the relative position of the two wedges, and then change the total thickness of the wedges to adjust the size of the discharge opening.

-

Hydraulic adjustment

Hydraulic adjustment is to replace the adjusting screw in mechanical adjustment with a hydraulic cylinder. At the same time, the adjustment of tensioning spring is also realized by a hydraulic cylinder. This realizes the automatic adjustment of the discharge opening, which is convenient and labor-saving.

Gasket adjustment or wedge adjustment, which is better?

In a comprehensive view, the gasket adjustment is the simplest but inconvenient to operate. The wedge adjustment can realize automatic adjustment and is more convenient to operate. But this is only the adjustment that can be made when the worn parts are lost in a certain proportion. If the worn parts are seriously lost, it is still recommended to replace them.

Hydraulic cylinder adjustment- An up-to-date adjustment method

Hydraulic cylinder adjustment can automatically adjust the discharge opening and realize the function of over-iron and cavity clearing. This adjustment method is easy to use and reduces the operator’s labor intensity. But the use of relatively less, the price is relatively expensive, now is not widely popular.