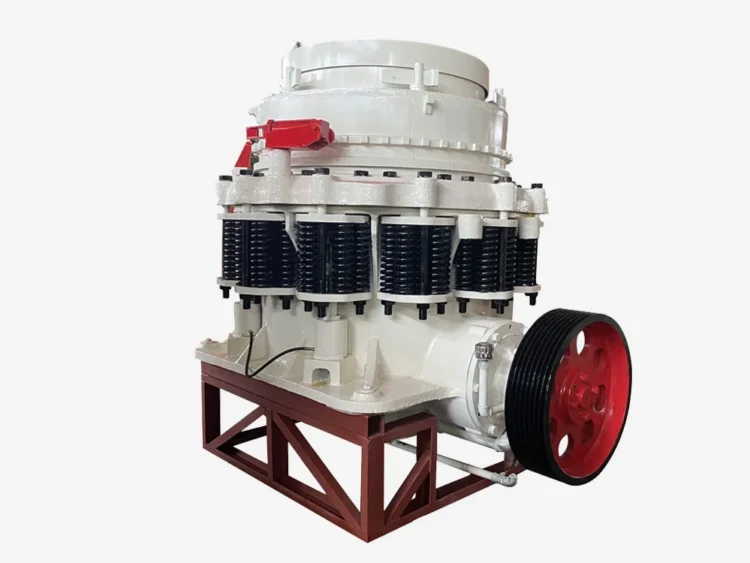

Advantages Of Single-Cylinder Hydraulic Cone Crusher

CS Single-Cylinder Hydraulic Cone Crusher is the world’s most advanced crushing machine. It is an integrated machinery with hydraulic pressure, electricity, and intelligent control. This machine adopts a brand-new crushing structure, optimized crushing cavity, and intelligent control system. It is suitable for medium, fine and ultra-fine crushing operations.

1.Simple structure, strong and durable, easy to maintain, low running cost

2.Larger production capacity, high crushing efficiency, low energy consumption

3.Constant cavity design concept, the longer service life of liner plate

4.Full automatic control system to ensure safe operation of the equipment

Prices Of Single-Cylinder Hydraulic Cone Crusher

The prices are different depend on different crusher models. As the leading mining crusher manufacturer with almost 30 year history in China, we will provide maximum preferential price and discount for you. Welcome to visit our company and factory.

Technical Data Of Single Cylinder Hydraulic Cone Crusher

| Type | Stroke | Max. feeding size(mm) |

Nominal capacity in t/h with crusher running at css mm | Power(kw) | |||||||

| 8 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | ||||

| CH440 | 25 | 200 | 100-200 | 110-130 | 135-155 | 160-180 | 190-210 | 210-235 | 240-265 | 220 | |

| 32 | 200 | 110-130 | 120-150 | 165-195 | 195-225 | 230-260 | 265-285 | 390-320 | 220 | ||

| 40 | 200 | 150-170 | 205-230 | 245-280 | 290-330 | 325-360 | 220 | ||||

| CH660 | 25 | 270 | 130-150 | 155-175 | 180-200 | 210-230 | 230-275 | 280-340 | 350-410 | 315 | |

| 32 | 270 | 140-170 | 185-215 | 215-275 | 280-360 | 385-465 | 480-560 | 570-630 | 315 | ||

| 40 | 270 | 225-250 | 260-320 | 330-390 | 415-475 | 315 | |||||

| CS440 | 25 | 330 | 210-235 | 240-260 | 220 | ||||||

| 32 | 330 | 265-295 | 300-330 | 220 | |||||||

| 40 | 330 | 360-450 | 430-510 | 535-585 | 220 | ||||||

| CS660 | 25 | 430 | 330-350 | 360-430 | 315 | ||||||

| 32 | 430 | 420-490 | 510-580 | 570-630 | 315 | ||||||

| 40 | 430 | 480-560 | 560-670 | 680-750 | 315 | ||||||