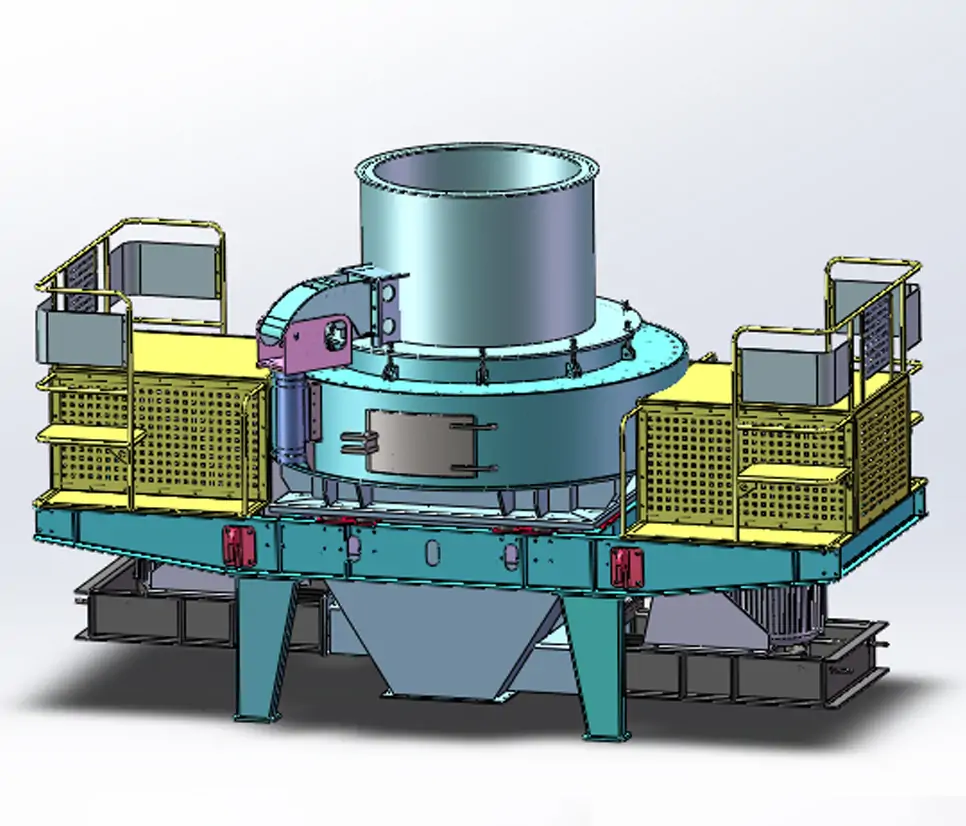

Advantages Of 5X Vertical Shaft Impact Crusher

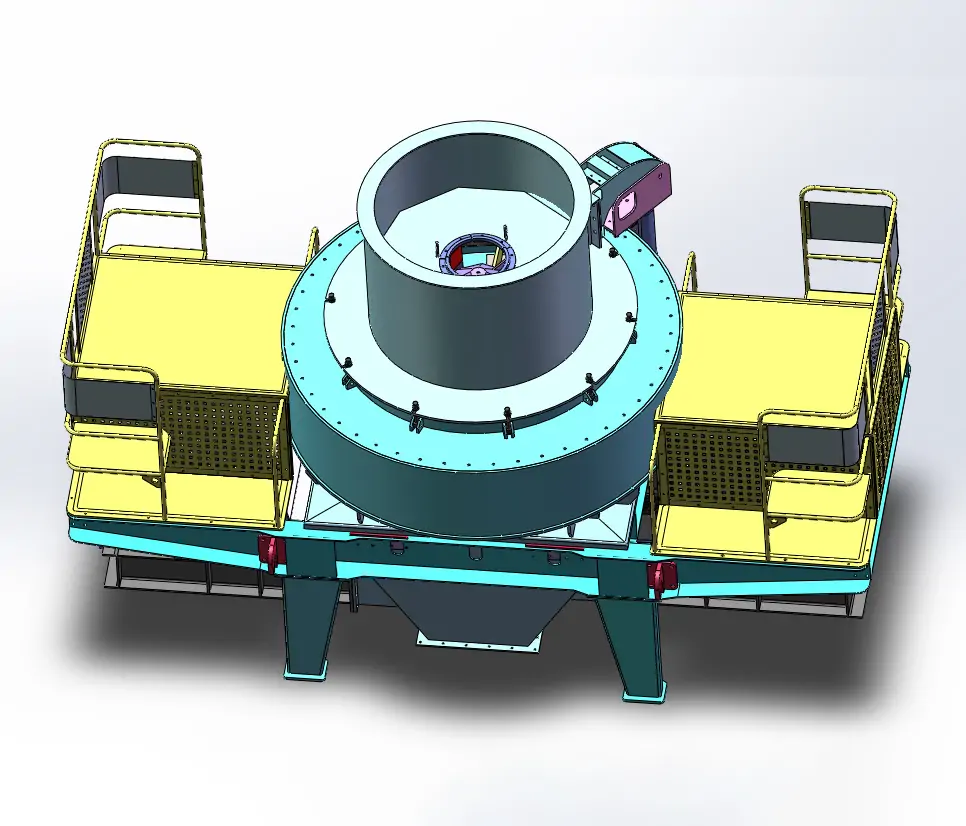

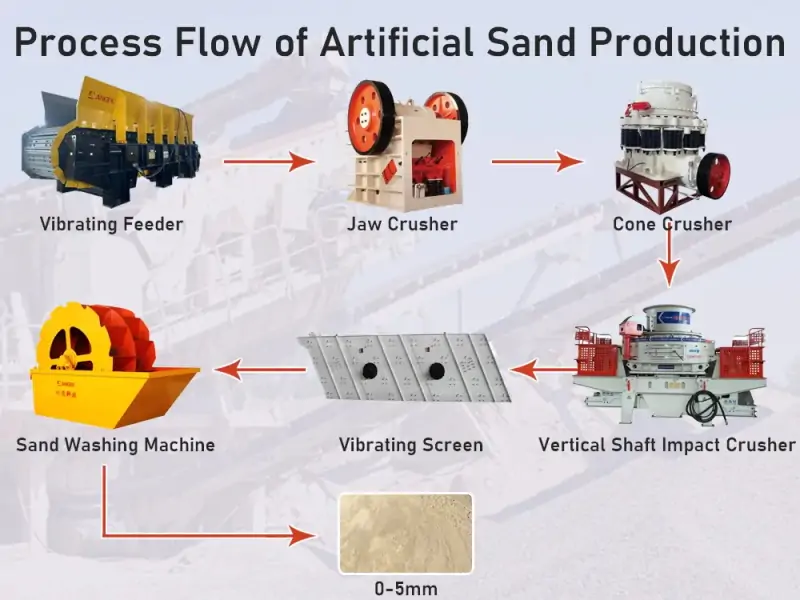

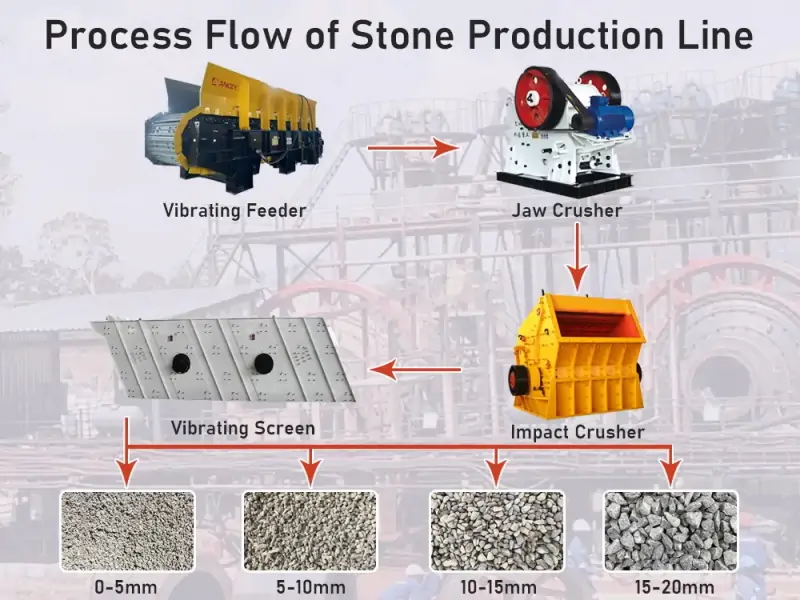

The 5X VSI Sand Making Machine is a secondary or tertiary fine crushing equipment. It includes the sand-making, shaping, and crushing process. The applied materials are hardness and higher hardness materials. It is popular in construction, industrial ore, and metal ore.

1. Sand making and shaping combined

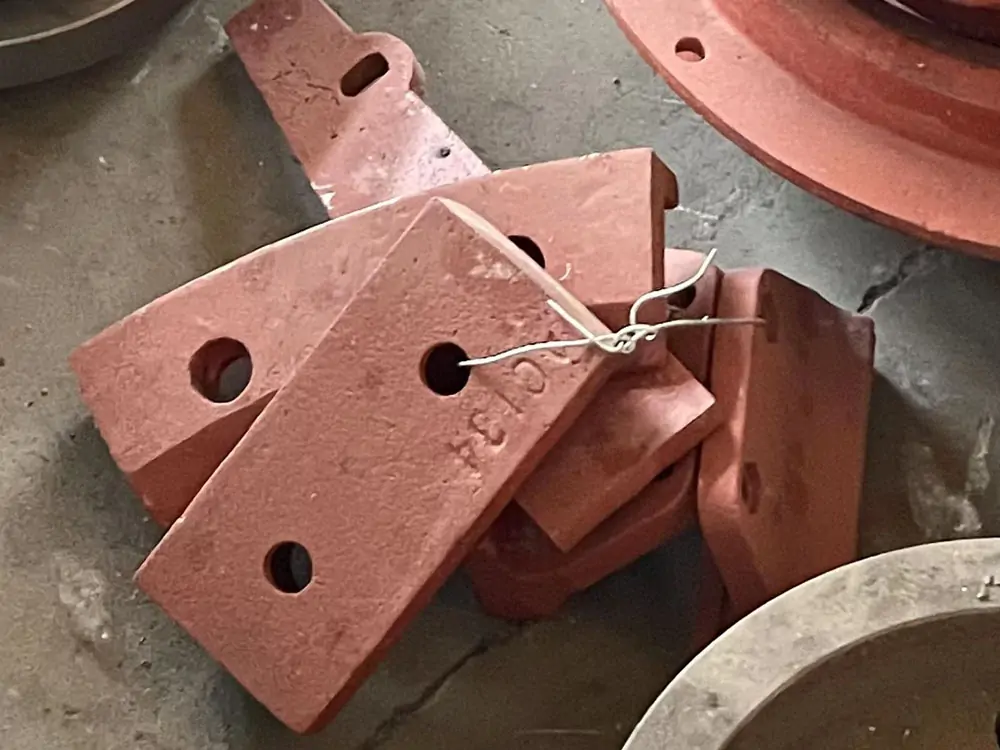

2. Easy to replace wear parts

3. Uniformed feeding size and controllable feeding speed

Prices Of 5X Vertical Shaft Impactor

The 5X Vertical Shaft Impact Sand Making Machine prices are different depend on different crusher models. As one of the leading VSI crusher manufacturers in China, we will provide maximum preferential price and discount for you. Welcome to visit our company and factory.

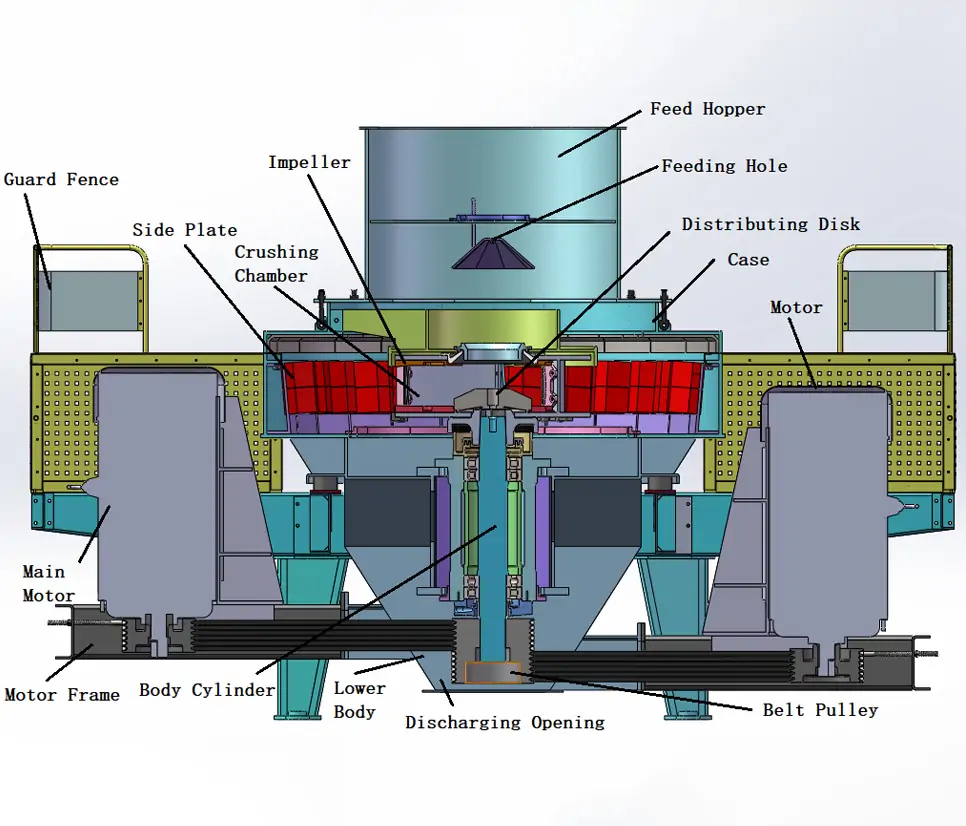

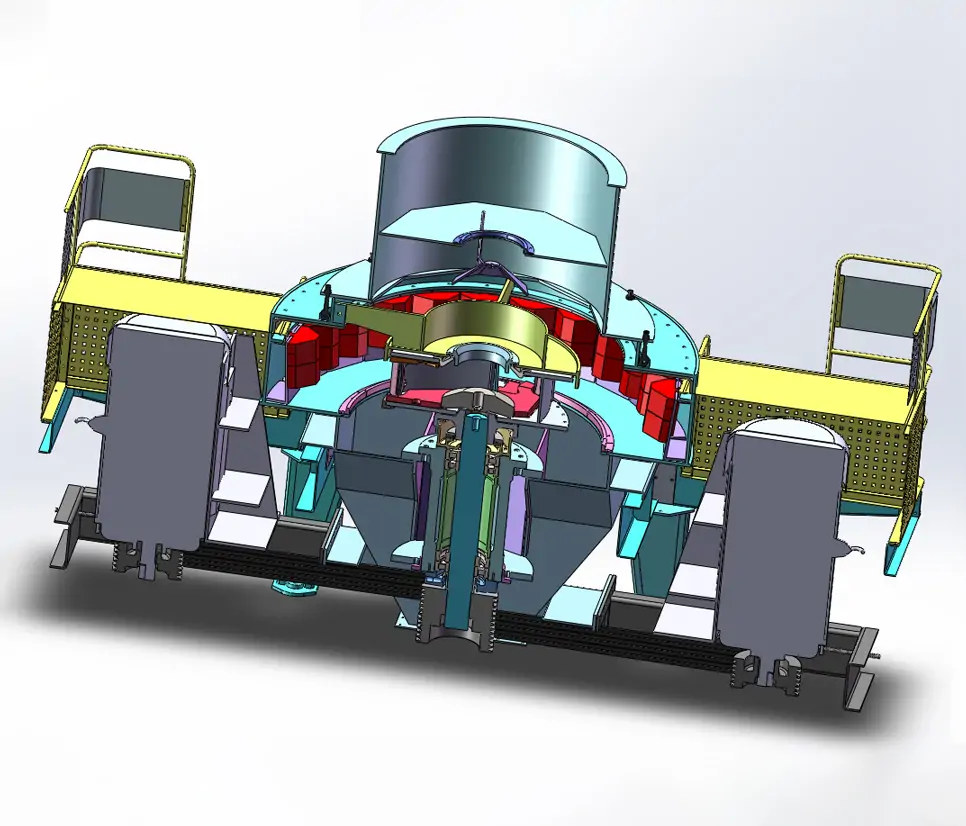

The working principle of 5X Vertical Shaft Impact Crusher

There are mainly two forms of “stone-hit-stone” and “stone-hit- iron.” The “stone-hit-stone” is used for processing materials with strong abrasiveness, and the “stone-hit- iron” is used for processing materials with low abrasiveness.

“stone-hit-stone”:

The “stone-hit-stone” form refers to the center material drop accompanied by a circular waterfall material drop. The material enters the sand making machine from the feed hopper and is divided into two parts by the separator. One part enters the impeller with high speed in the middle of the separator and is accelerated rapidly in the impeller. The acceleration can reach hundreds of times the acceleration of gravity, and then it is thrown out from the three evenly distributed flow channels of the impeller at a speed of 60-70m/s. First of all, the material is broken by the impact of a part of the material falling from around the divider and then impacted together to the material lining layer in the vortex support cavity, which is rebounded by the material lining layer and impacted upward to the top of the vortex cavity obliquely. And change its direction of motion, deflection downward movement, and from the impeller flow channel to launch the material to form a continuous material curtain. In this way, a piece of material in the vortex crushing cavity is subject to two or more times of impact, abrasion, and grinding crushing. Finally, the crushed material is discharged from the lower discharge port.

“stone-hit- iron”:

The form of “stone-hit- iron” refers to the complete center material drop. The material enters the sand making machine from the feed hopper through the middle of the separator and enters the high-speed rotating impeller, which is rapidly accelerated inside the impeller. Then with a speed of 60-70 m/s, it is ejected from the three evenly distributed flow channels of the impeller, and impacts the material lining layer in the vortex support cavity, which is rebounded by the material lining layer and impacts upward diagonally to the top of the vortex cavity, then changes its direction of motion and deflects downward, forming a continuous material curtain with the material emitted from the flow channels of the impeller. Finally, the crushed material is discharged from the lower discharge port.

Precautions on the installation and use of the sand making machine

Sand-making machine belongs to heavy equipment, and their installation and use need certain rules and instructions. Here we will see which aspects of its installation and use need to be noted:

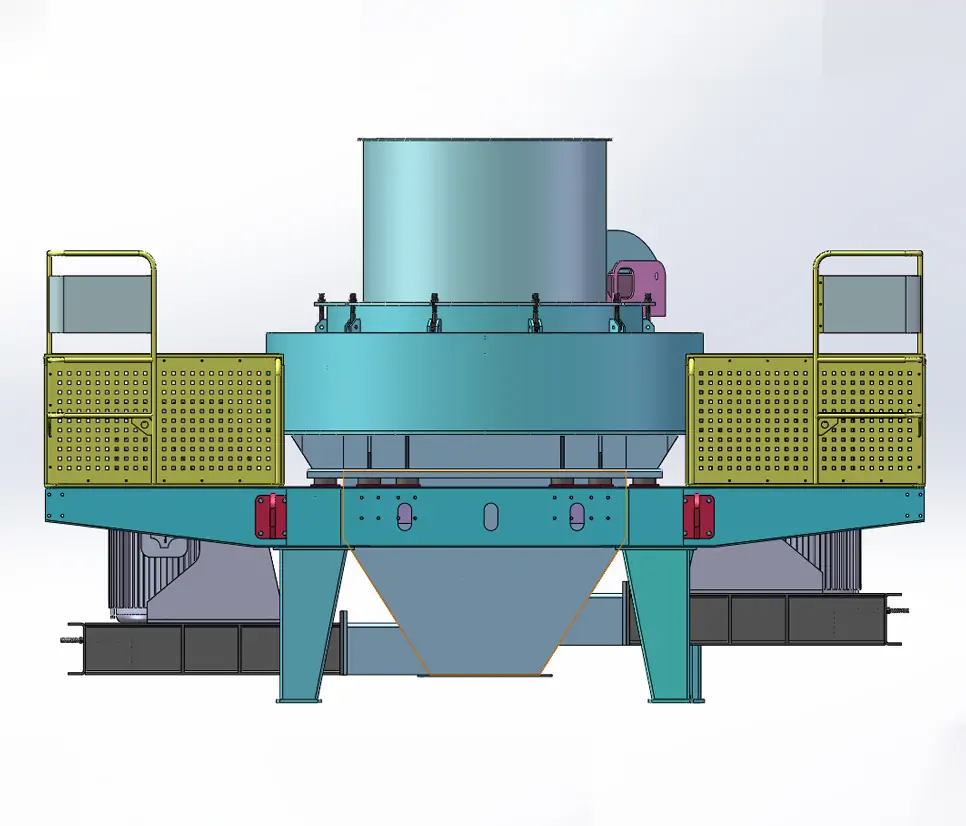

1. Sand-making machine installed on a concrete foundation. The foundation should bear several times the weight of the whole machine. When installed, the sand-making machine should be leveled so that its main shaft is vertical to horizontal.

2. The rotational direction of the impeller of the sand-making machine should be consistent with the direction of the label of the sand-making machine. If it is opposite to the label’s direction, the motor wiring should be adjusted so that the direction of rotation is consistent with the label. Directional rotation is strictly prohibited.

3. Sand-making machine feed size strictly according to the requirements. Entering the sand-making machine with materials larger than those specified is strictly forbidden. Otherwise, it will cause unbalance of the impeller of the sand-making machine and excessive wear of the impeller, and even cause blockage of the impeller channel and the central feeding tube so that the sand-making machine cannot work normally. Large materials should be excluded in time. The crushing ratio of the sand-making machine is generally around 10. (Note: For example, the crushing ratio of 50MM material into 5MM is called 10).

4. The starting sequence of the sand-making machine and conveying equipment is: discharging material – crusher – feeding material. The stopping sequence is opposite to the starting sequence. The sand-making machine must be started with no load after the crusher normally runs direction feed.

5. The crusher must not have violent vibration and abnormal noise during operation; otherwise, it should stop and check.

Technical Data Of 5X Vertical Shaft Impact Crusher

| Type | 5*7615 | 5*8522 | 5*9532 | 5*1145 | 5*1150 | 5*1263 | |

| Feeding size(mm) | soft material | <35 | <40 | <45 | <50 | <55 | <60 |

| hard material | <30 | <35 | <40 | <45 | <45 | <50 | |

| Capacity(t/h) | feed both at center and at sides | 150-280 | 240-380 | 350-460 | 450-550 | 500-600 | 550-660 |

| feed at center | 70-140 | 120-190 | 180-280 | 250-360 | 340-410 | 340-410 | |

| Rotation speed (r/min) | 1700-1900 | 1500-1700 | 1300-1510 | 1100-1380 | 1000-1300 | 960-1210 | |

| Double motor power(kw) | 2*75(55) | 2*110(90) | 2*160(132) | 2*220(200) | 2*250 | 2*315(280) | |

| Dimesion(L*W*H)(mm) | 4100*2330*2300 | 4140*2500*2700 | 4560*2600*2900 | 5100*2790*3320 | 5500*2750*3950 | 5690*2966*3396 | |

| lubrication station | motor power of double oil pump(kw) | 2*0.25(0.75) | |||||

| safety assuance | Double oil pumps assure enough oil supply;automatic switch off with no oil stream or pressure;air cooling in summer,motor hearing stare-up in winter | ||||||

| power of oil tank heater(kw) | 2(4) | ||||||

| Dimesion(L*W*H)(mm) | 818*520*1280 | ||||||