Advantages Of PEX, PE Jaw Crusher

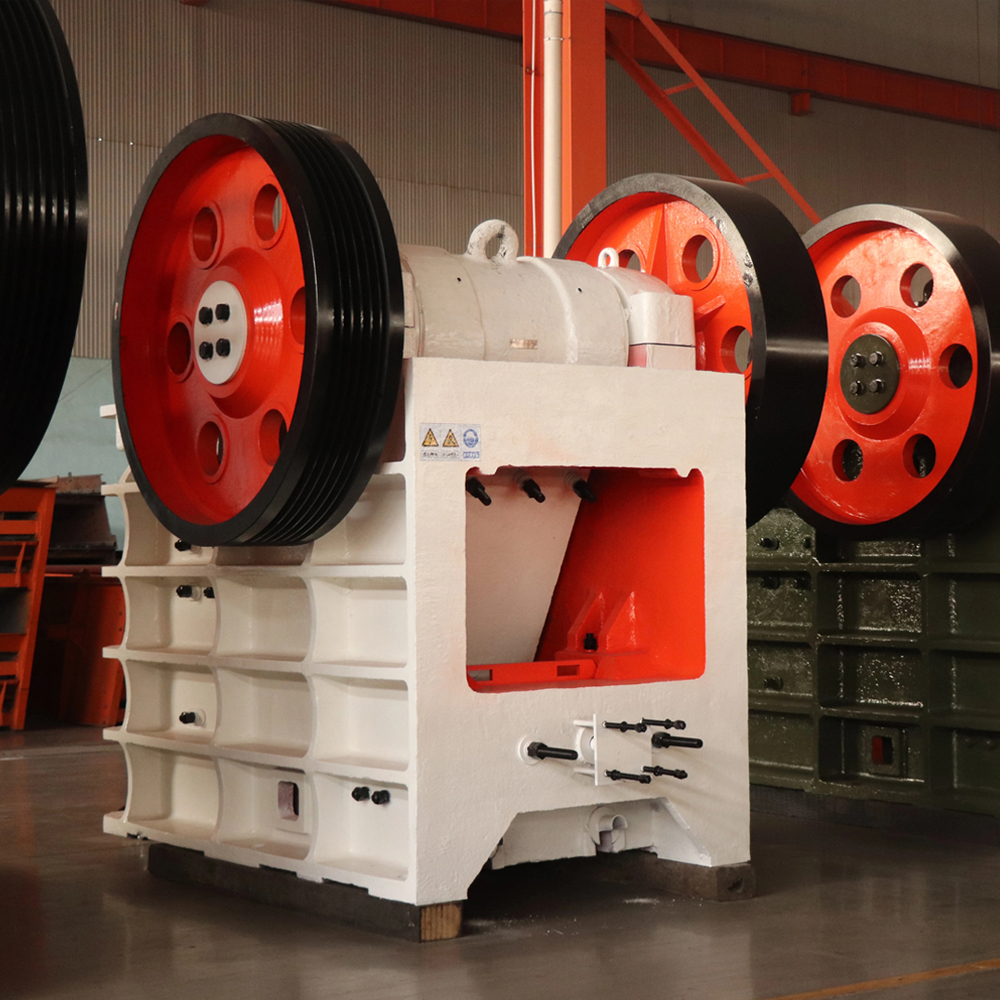

1. Cast and welded PEX/PE jaw crusher is available

Compared with welding PEX/PE jaw crusher of competitors, we have our own casting workshop. We supply casting and welding choices for customers.

2. The outlet size is adjustable and the outlet shims are easy to exchange and maintain

3. Deep cavity structuredesign, more energy-saving

The deep cavity design increases output capacity. It brings a larger crushing ratio. It also gets crushing material in uniform sizes.

Prices Of PE, PEX Jaw Crusher

PE, PEX Jaw Crusher prices are different depend on different crusher models. As the leading mining crusher manufacturer with almost 30 year history in China, we will provide maximum preferential price and discount for you. Welcome to visit our company and factory.

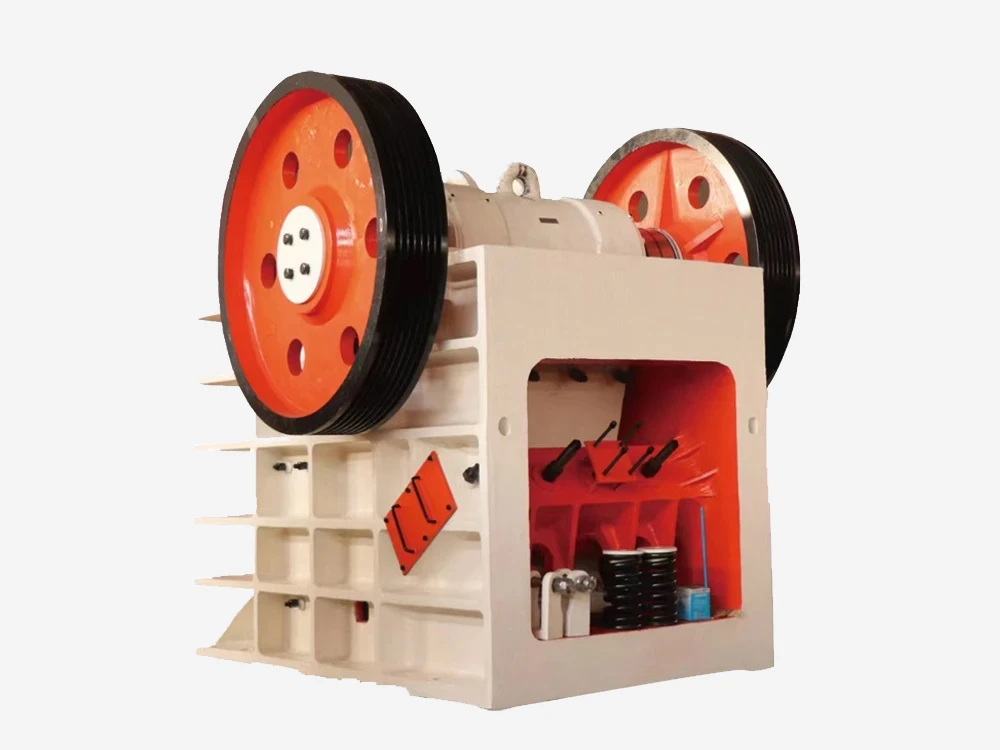

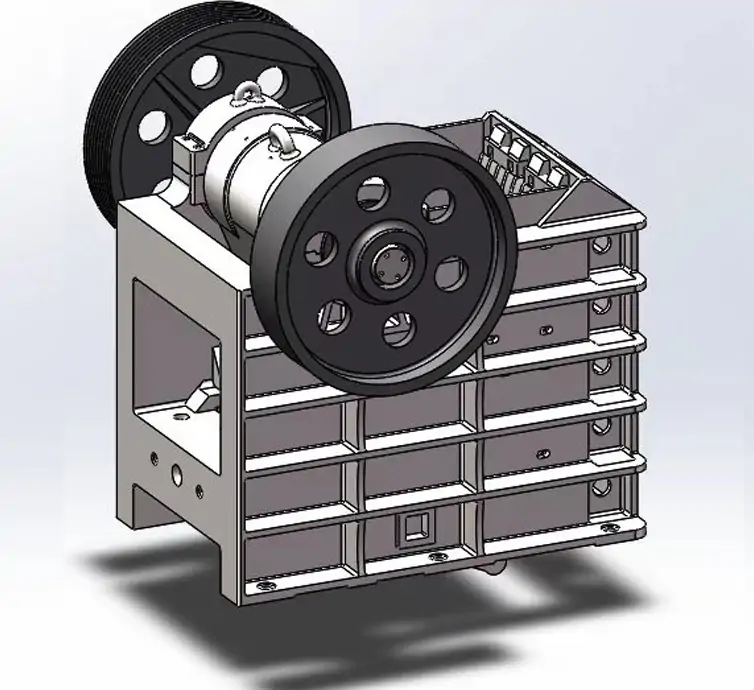

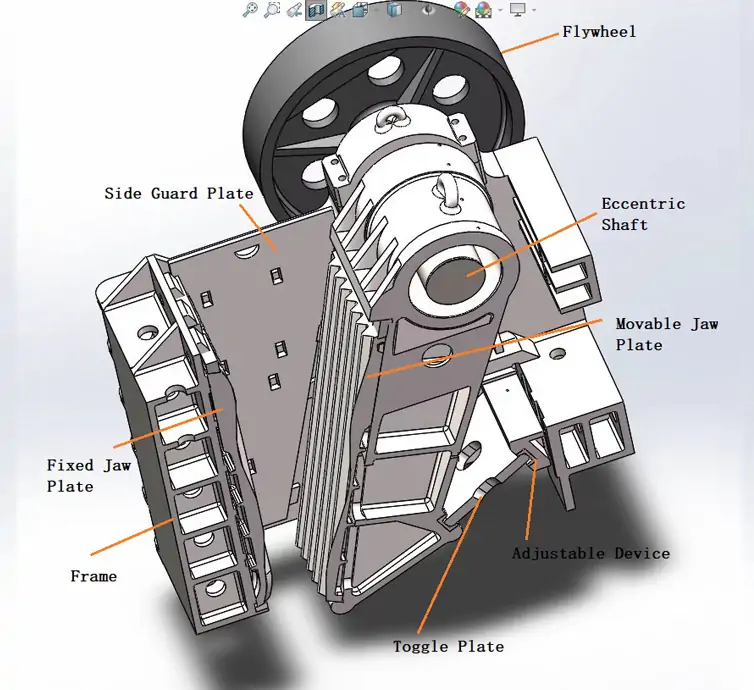

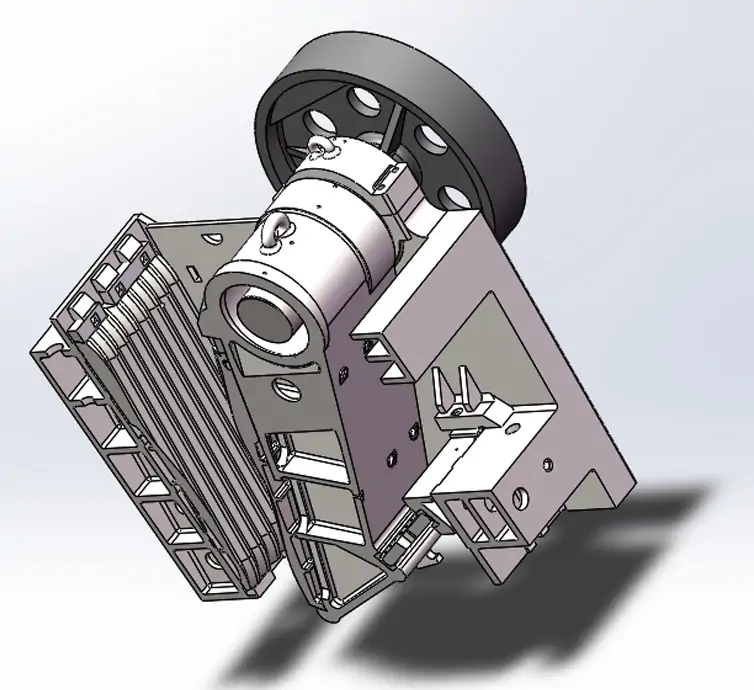

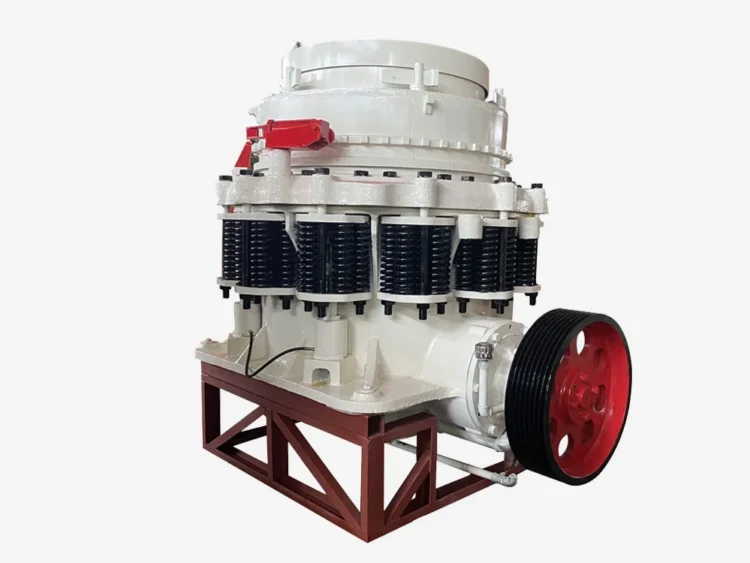

Structure of PE jaw crusher

A jaw crusher is mainly composed of a frame, fixed jaw plate, movable jaw plate, guard plate, transmission parts, adjusting the seat, moving jaw lever, etc.

Frame

The frame is a four-walled rigid frame with upper and lower openings, which is used to support the eccentric shaft and bear the reaction force of the crushing material, requiring sufficient strength and rigidity. For large machines, the frame is cast in sections and then firmly linked with bolts to form a whole, which is a complex casting process. The frame of a small homemade jaw crusher can also be made of thick steel plates welded together, but the rigidity is poor.

Jaws and side guards

Both the fixed and moving jaws consist of a jaw bed and a jaw plate, which is the working part and is bolted to the jaw bed with a wedge iron. The jaw bed of the fixed jaw is the front wall of the frame, and the jaw bed of the movable jaw is suspended on the circumference to have enough strength and stiffness to bear the crushing reaction force. Thus most of them are cast steel or cast iron parts.

Transmission Parts

The eccentric shaft is the main shaft of the crusher, which is subject to huge bending and torsional forces and is made of high-carbon steel. It is subject to finishing and heat treatment, and the bearing liner is cast in the pasteurized alloy. The eccentric shaft has a pulley at one end and a flywheel at the other.

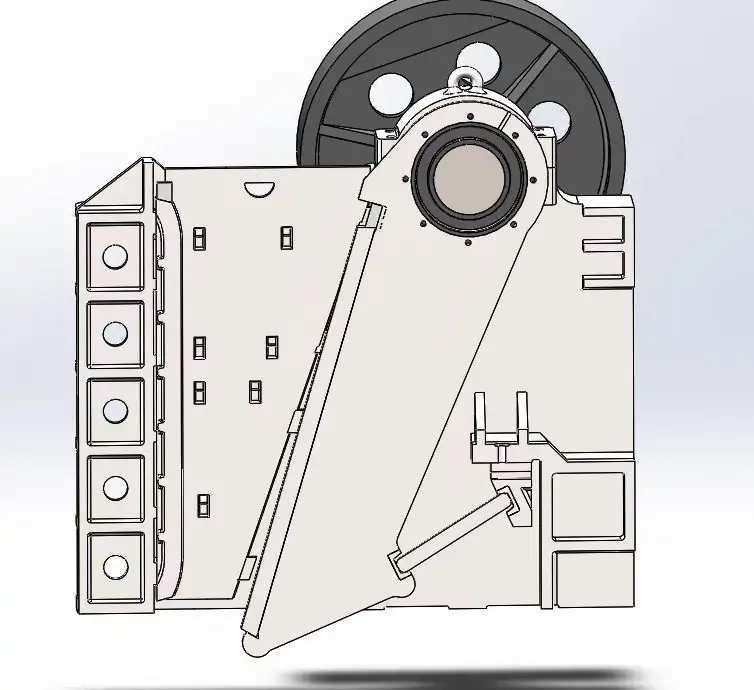

What is the working principle of jaw crusher?

The jaw crusher crushing method is a curved extrusion type, and the operation principle is to simulate the movement of two jaws of animals. When the jaw rises, the angle between the elbow plate and the jaw becomes larger, thus pushing the jaw plate closer to the fixed jaw plate, and the material is crushed by the extrusion, rubbing and grinding between the two jaw plates; when the jaw goes down, the angle between the elbow plate and the jaw becomes smaller, and the jaw plate leaves the fixed jaw plate under the action of the tie rod, and spring and the crushed material is discharged freely by gravity. The crushed material is discharged freely through the discharge port in the lower part of the jaw cavity under the action of gravity. With the continuous rotation of the motor, the jaw crushes and discharges the material periodically to realize mass production.

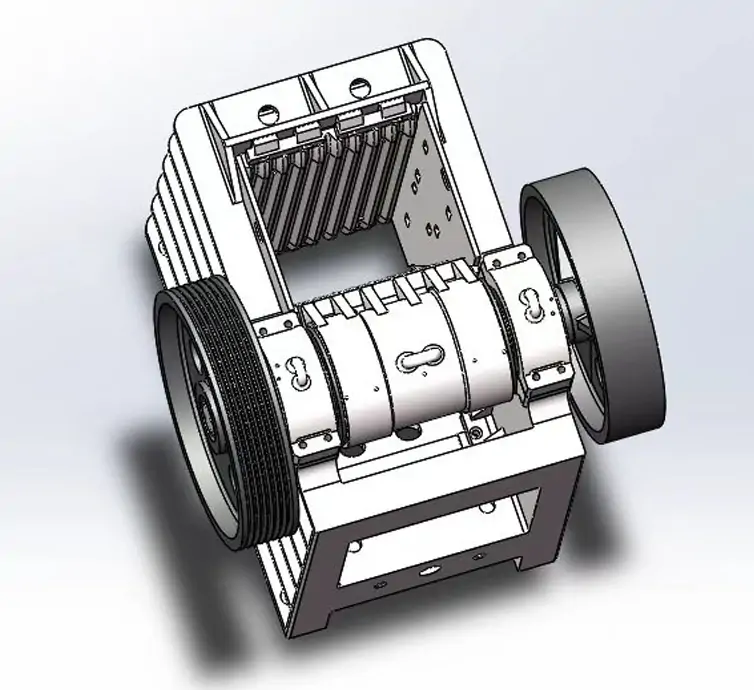

Technical Advantages of PE Jaw Crusher

The crushing cavity of the jaw crusher is a V-shaped deep cavity, which can improve the feeding capacity and output of the jaw crusher to a certain extent; even if it is a small-sized jaw crusher, it also has certain advantages compared with other crushers in terms of output working capacity. At the same time, the jaw crusher adopts the new design of flywheel, which can effectively reduce the machine vibration and ensure the machine’s smooth operation.

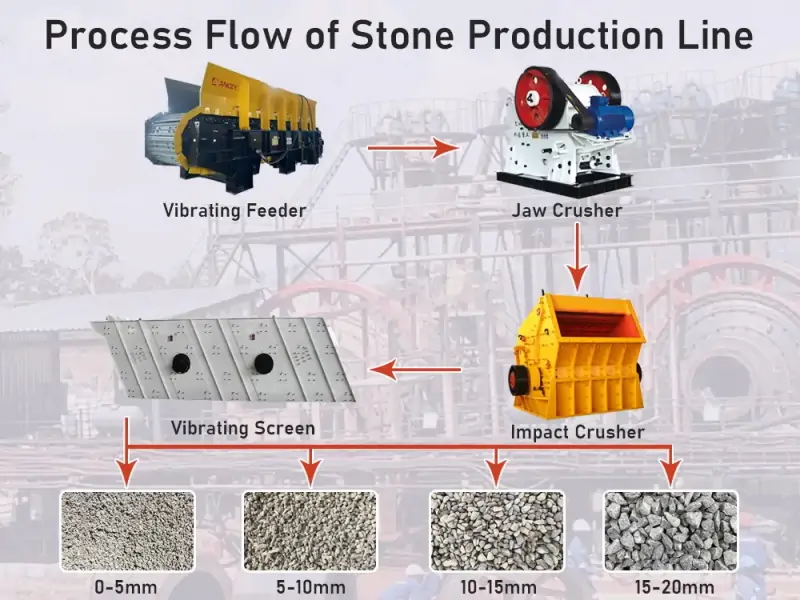

From the point of view of applicable industries, jaw crusher has a wide range of applications in mining crushing but also plays an essential role in building materials, highways, railroads, and chemical and water conservancy industries. From the point of view of applicable materials, such as quartz stone, green stone, river pebbles, cobblestone, limestone, iron ore, concrete, and other large stone crushing is possible to use the jaw crusher.

Technical Data Of PE, PEX Jaw Crusher

| Type&Specification | Max. feeding size(mm) |

Discharge range opening(mm) | Capacity(t/h) | Power(kw) | Weight(t) | Dimesion(L*W*H)(mm) |

| ZG-PE-150*250 | 125 | 10-40 | 2-6 | 5.5 | 1 | 900*750*950 |

| ZG-PE-250*400 | 210 | 20-60 | 8-16 | 15 | 3 | 1450*1280*1300 |

| ZG-PE-400*600 | 350 | 40-100 | 20-40 | 30 | 6 | 1700*1700*1650 |

| ZG-PE-500*750 | 400 | 50-120 | 30-80 | 45 | 11 | 2000*1950*1900 |

| ZG-PE-600(A)*900 | 425 | 60-130 | 45-95 | 55 | 12.5 | 2200*1960*1950 |

| ZG-PE-600*900 | 480 | 75-200 | 80-200 | 75 | 18 | 2400*2230*2400 |

| ZG-PE-700*1000 | 550 | 80-210 | 90-240 | 75 | 19.5 | 2400*2280*2400 |

| ZG-PE-750*1060 | 630 | 80-235 | 120-300 | 90 | 26 | 2500*2370*2780 |

| ZG-PE-900*1200 | 750 | 95-265 | 280-500 | 110 | 45 | 3200*2820*3260 |

| ZG-PE-1100*1400 | 900 | 120-260 | 350-750 | 200 | 75 | 3850*3050*4000 |

| ZG-PE-1200*1500 | 1020 | 150-300 | 700-950 | 250 | 85 | 4050*3150*4200 |

| ZG-PE-1300*1600 | 1200 | 220-550 | 800-1200 | 355 | 122 | 5100*4700*4300 |

| ZG-PE-1500*1800 | 1250 | 280-650 | 1000-1400 | 500 | 169 | 5600*5020*4950 |

| ZG-PEX-150*750 | 120 | 10-40 | 8-25 | 15 | 3.1 | 1320*1570*1050 |

| ZG-PEX-150*1000 | 140 | 15-45 | 12-35 | 22 | 5 | 1400*1810*1250 |

| ZG-PEX-200*1000 | 160 | 15-50 | 12-40 | 22 | 5 | 1530*1810*1250 |

| ZG-PEX-250*750 | 210 | 20-60 | 15-40 | 30 | 5.5 | 1480*1710*1470 |

| ZG-PEX-250*1000 | 210 | 20-60 | 20-50 | 30 | 6.5 | 1530*1920*1380 |

| ZG-PEX-350*750 | 300 | 20-60 | 30-80 | 30 | 7.5 | 1650*1850*1640 |

| ZG-PEX-200*1200 | 200 | 20-60 | 30-100 | 37 | 8.5 | 1650*2150*1460 |

| ZG-PEX-250*1200 | 210 | 20-60 | 40-120 | 45 | 8.5 | 1650*2150*1460 |

| ZG-PEX-300*1300 | 250 | 20-90 | 60-180 | 55 | 11 | 1870*2400*1730 |

| ZG-PEX-350*1500 | 300 | 20-90 | 80-220 | 75 | 15 | 1900*2660*1830 |

| ZG-PEX-600*1500 | 550 | 45-120 | 120-260 | 90 | 22 | 2200*2750*2200 |