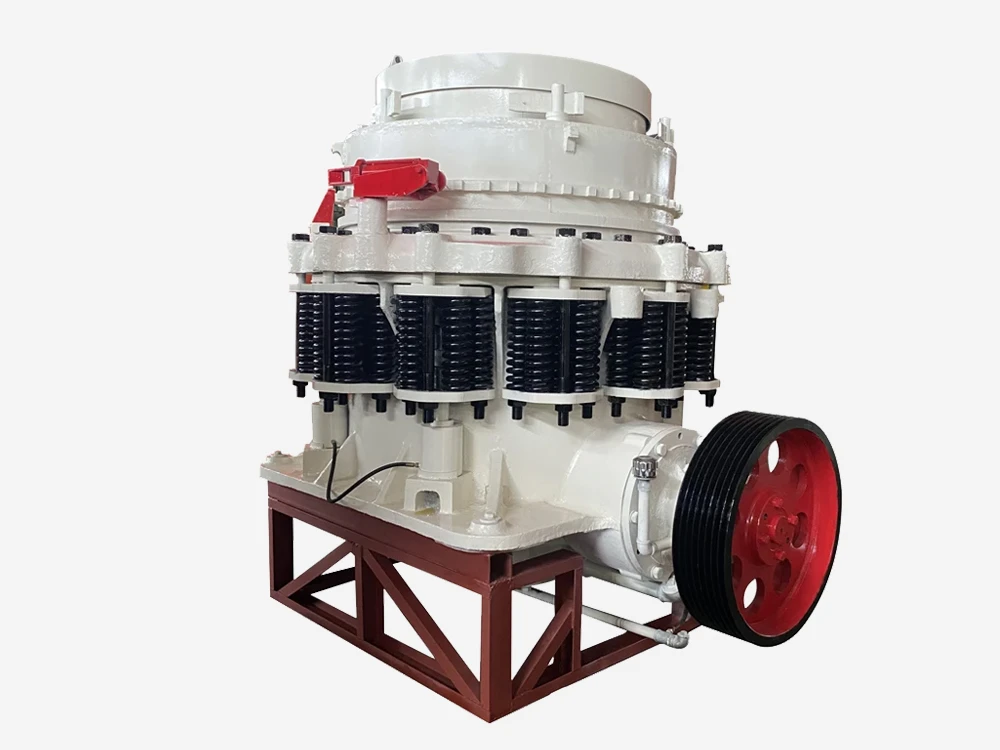

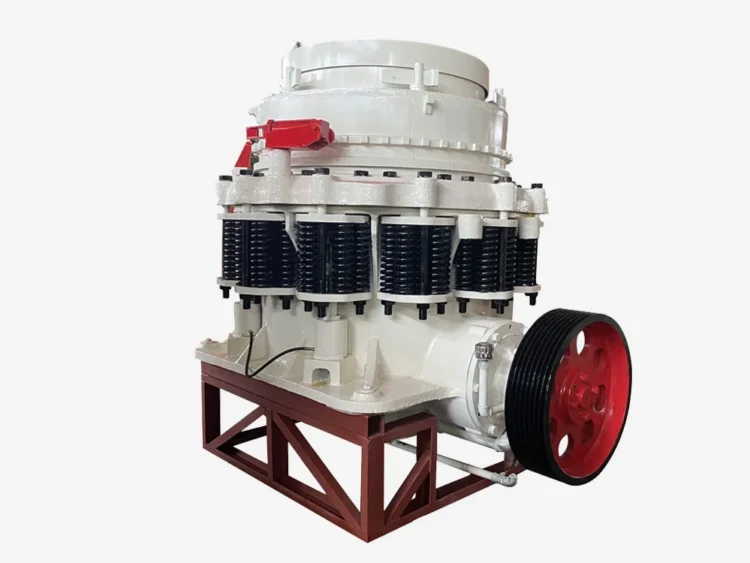

Advantages Of Spring Cone Crusher

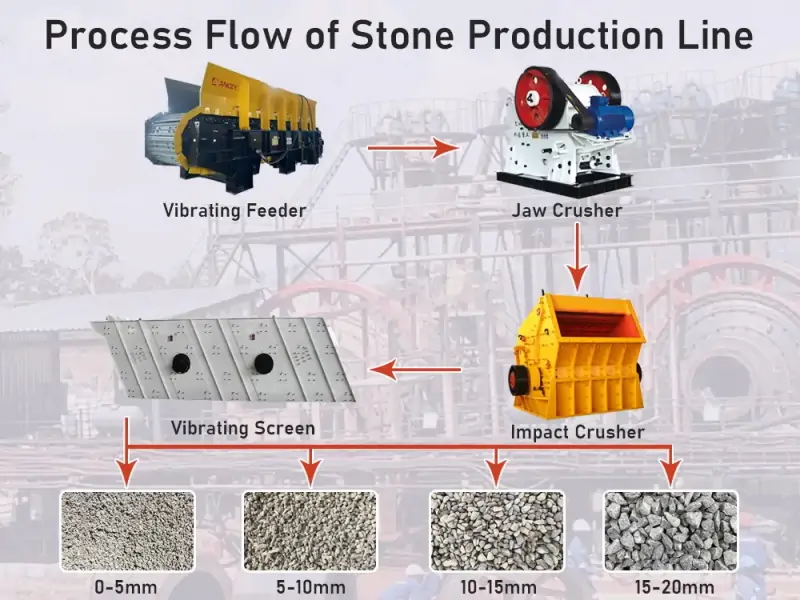

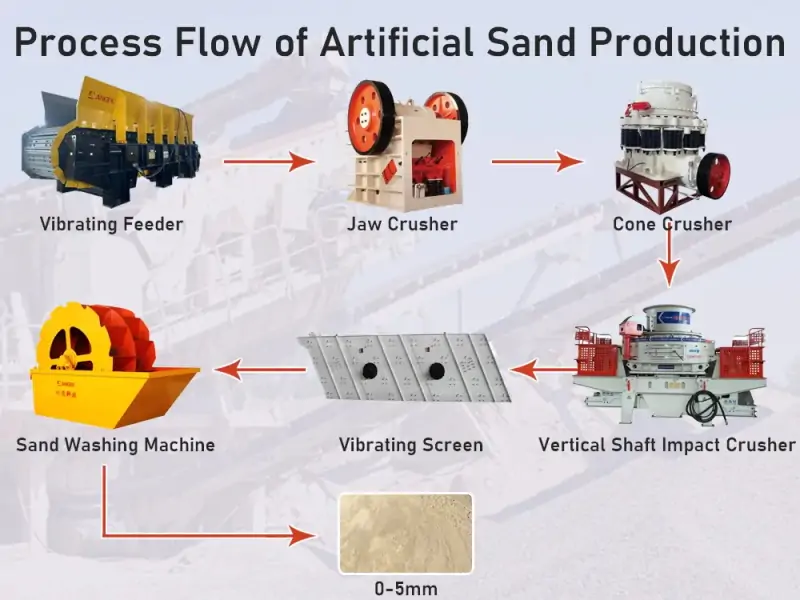

The Spring cone crusher has a large crushing ratio, high efficiency, low energy consumption, and uniform product size. It is suitable for medium and fine crushing various ores and rocks. For example, iron ore, copper ore, limestone, granite, basalt, etc.

1. Large crushing ratio, high production efficiency

2. Low consumption wearing parts, low operating costs, and least maintenance costs. Service life increases by more than 30%

3. Hydraulic protection, hydraulic cavity cleaning, reduce downtime

4. Reliable and advanced low-concentration oil lubrication

5. Variety of crushing cavity types, flexible application

6. Simple maintenance, easy to handle

7. Higher production capacity, better product shape, valuable to the customer

Application areas: mining, smelting, building materials, highway, railroad, water conservancy and chemical industry, etc.

Prices Of Spring Cone Crusher

Spring Cone Crusher prices are different depend on different crusher models. As the leading mining crusher manufacturer with almost 30 year history in China, we will provide maximum preferential price and discount for you. Welcome to visit our company and factory.

What is the working principle of Spring Cone Crusher?

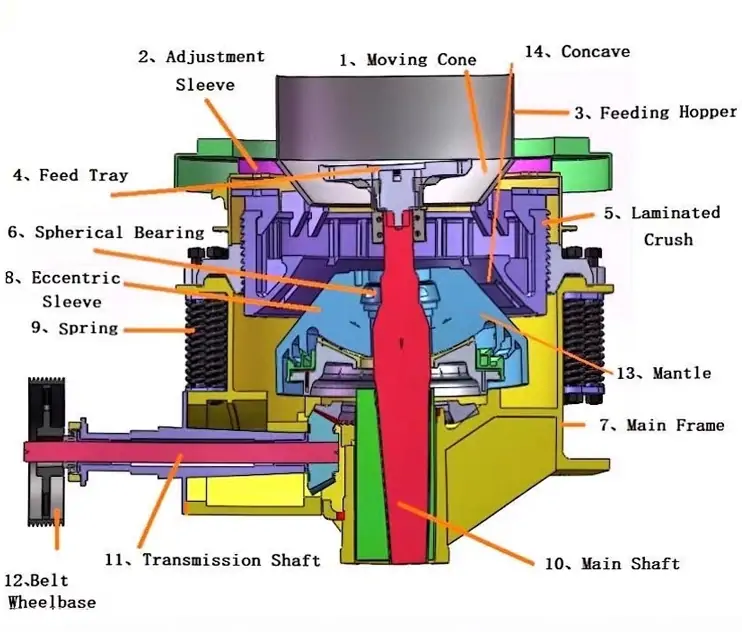

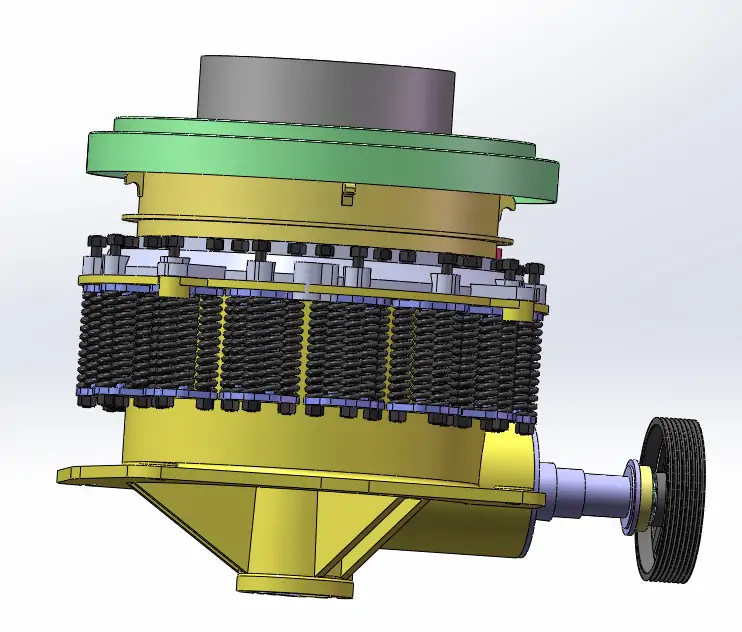

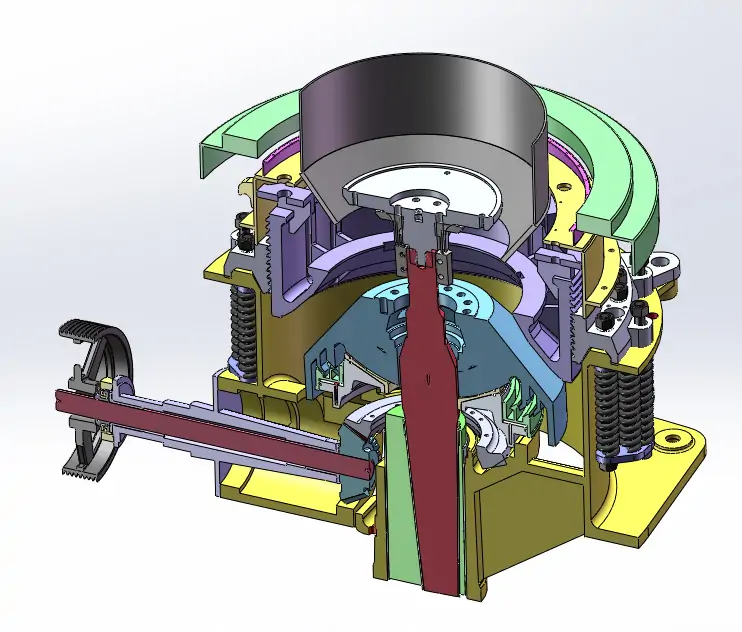

The structure of cone crusher mainly consists of frame, horizontal shaft, moving cone, balance wheel, eccentric sleeve, upper crushing wall (fixed cone), lower crushing wall (moving cone), lubrication system, hydraulic system, control system and other parts.

When the Spring cone crusher is in operation, the electric motor drives the eccentric sleeve to rotate through the transmission device. The moving cone is forced to swing by the eccentric sleeve, and the section of the moving cone near the static cone becomes the crushing chamber. The material to be crushed enters through the inlet and is squeezed and impacted by the moving cone and the static cone several times to form the material with the required size. When the moving cone leaves this section, the formed material falls under its gravity and is discharged from the bottom of the cone.

Technical advantages of Spring cone crusher

1. The moving cone rotates continuously, and the crushing and discharging processes of the material are carried out along the working surface alternately. The productivity is high.

2. The material is sandwiched between the two cones and is squeezed, bent, and sheared. Crushing is easier, and the power consumption is lower.

3. The product material degree is more uniform, cubic shape. The wear of the working surface of the moving cone is also more uniform.

4. Both the moving cone and the fixed cone are orthotropic. When the moving cone is swinging, there is a parallel zone with an equal gap between the moving cone and the fixed cone near the discharge of the crushing chamber. This makes the finished material degree uniform. The size of the feed opening is not large, and all the materials that can be handled have been crushed for the first time.

Technical Data Of Spring Cone Crusher

| PYS-B standard type | Specifcation | Maximum diameter in cavity(mm) | Cavity | The mine mouth size (mm) | Discharge range opening(mm) | Capacity | Power(kw) | Weight(t) | |

| close side | open side | ||||||||

| PYS-B0910 | 3Ft | 914 | fine type | 83 | 102 | 9-22 | 40-100 | 75 | 14.64 |

| PYS-B0917 | rough type | 159 | 175 | 13-38 | 55-180 | ||||

| PYS-B0918 | super rough type | 163 | 178 | 25-38 | 105-180 | ||||

| PYS-B1313 | 4-1Ft | 1295 | fine type | 109 | 137 | 18-31 | 100-200 | 155 | 25.86 |

| PYS-B1321 | middle type | 188 | 210 | 16-38 | 118-280 | ||||

| PYS-B1324 | rough type | 216 | 241 | 19-51 | 155-384 | ||||

| PYS-B1325 | super rough type | 238 | 259 | 25-51 | 212-390 | ||||

| PYS-B1620 | 5-1/2Ft | 1676 | fine type | 188 | 209 | 16-38 | 162-360 | 240 | 50.8 |

| PYS-B1624 | middle type | 213 | 241 | 22-51 | 232-698 | ||||

| PYS-B1626 | rough type | 241 | 269 | 25-64 | 270-698 | ||||

| PYS-B1636 | super rough type | 331 | 368 | 38-64 | 388-745 | ||||

| PYS-B2127 | 7FtHD | 2134 | fine type | 253 | 278 | 19-38 | 344-798 | 380 | 89.5 |

| PYS-B2133 | middle type | 303 | 334 | 25-51 | 550-1098 | ||||

| PYS-B2136 | rough type | 334 | 369 | 31-64 | 710-1398 | ||||

| PYS-B2146 | super rough type | 425 | 460 | 38-64 | 800-1498 | ||||

| PYS-D short head type | Specifcation | Maximum diameter in cavity(mm) | Cavity | The mine mouth size (mm) | Discharge range opening(mm) | Capacity | Power(kw) | Weight(t) | |

| close side | open side | ||||||||

| PYS-D0904 | 3Ft | 914 | fine type | 13 | 41 | 3-13 | 24-100 | 75 | 14.64 |

| PYS-D0906 | rough type | 33 | 61 | 3-16 | 24-110 | ||||

| PYS-D0907 | super rough type | 51 | 76 | 6-19 | 54-140 | ||||

| PYS-D1306 | 4-1Ft | 1295 | fine type | 29 | 64 | 3-16 | 32-180 | 155 | 25.86 |

| PYS-D1308 | middle type | 54 | 89 | 6-16 | 74-180 | ||||

| PYS-D1310 | rough type | 70 | 105 | 8-25 | 98-250 | ||||

| PYS-D1313 | super rough type | 98 | 133 | 16-25 | 188-260 | ||||

| PYS-D1607 | 5-1/2Ft | 1676 | fine type | 35 | 70 | 5-13 | 82-230 | 240 | 50.8 |

| PYS-D1608 | middle type | 54 | 89 | 6-19 | 120-310 | ||||

| PYS-D1613 | rough type | 98 | 133 | 10-25 | 170-370 | ||||

| PYS-D1614 | super rough type | 117 | 133 | 13-25 | 228-370 | ||||

| PYS-D2110 | 7FtHD | 2134 | fine type | 51 | 105 | 5-16 | 172-450 | 380 | 89.5 |

| PYS-D2113 | middle type | 95 | 132 | 10-19 | 318-560 | ||||

| PYS-D2117 | rough type | 127 | 178 | 13-25 | 408-658 | ||||

| PYS-D2120 | super rough type | 152 | 203 | 16-25 | 530-718 | ||||