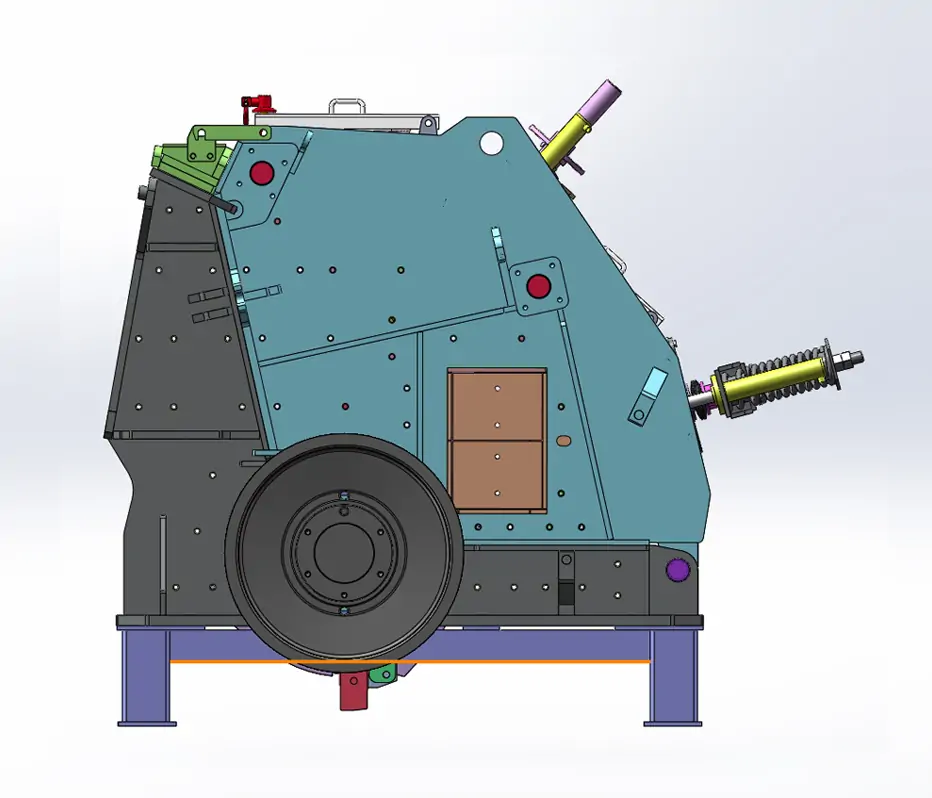

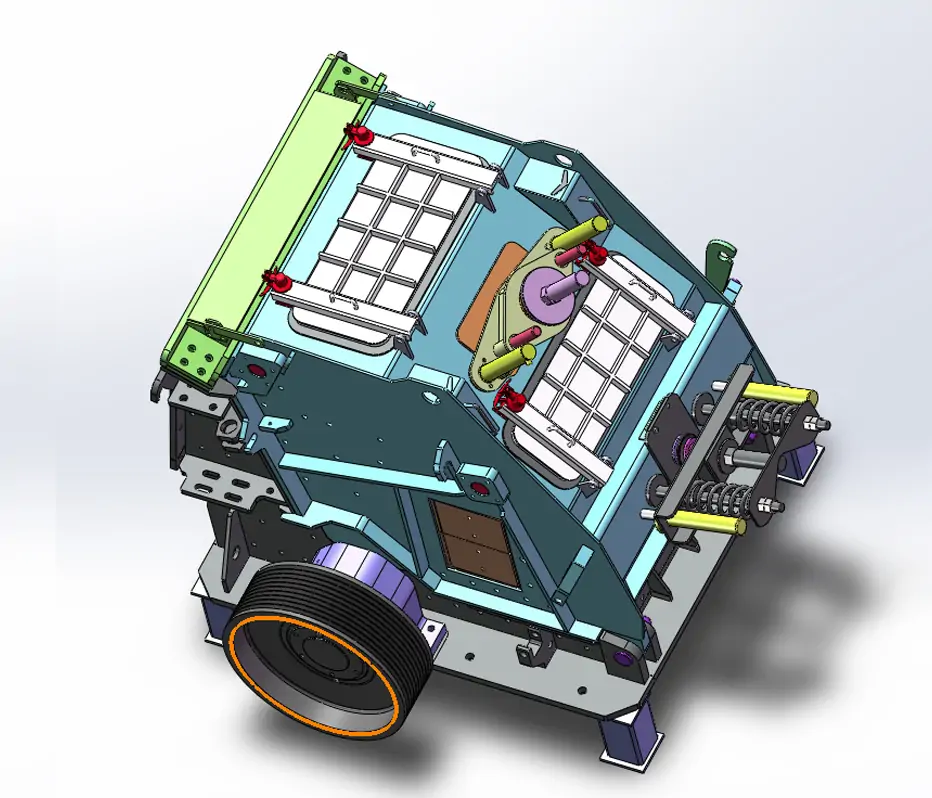

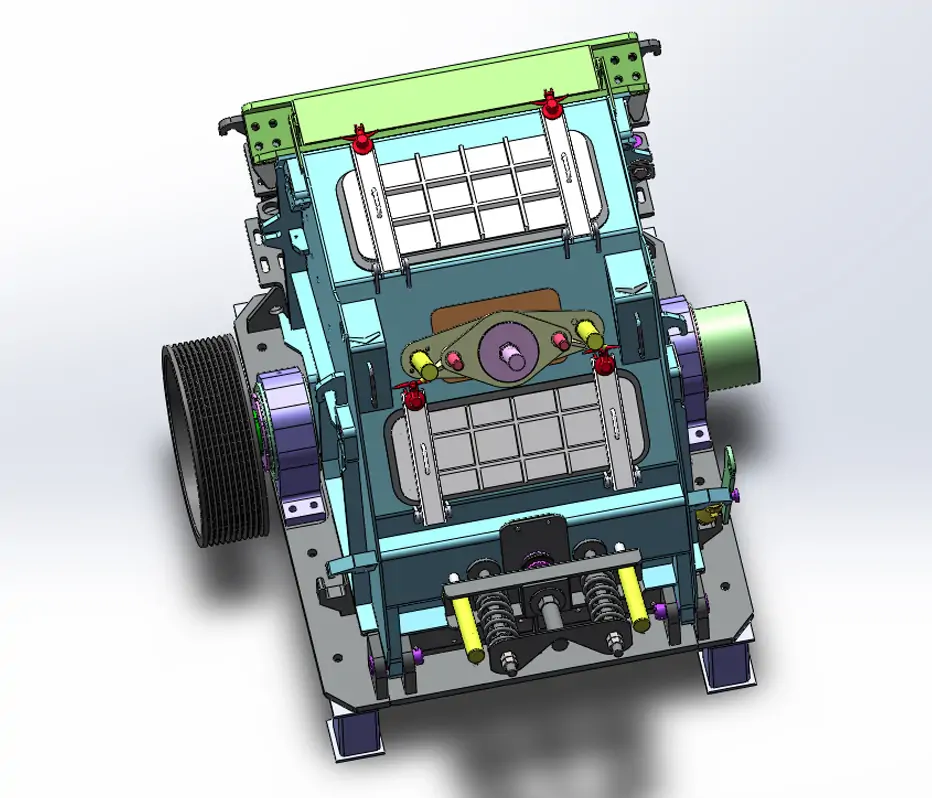

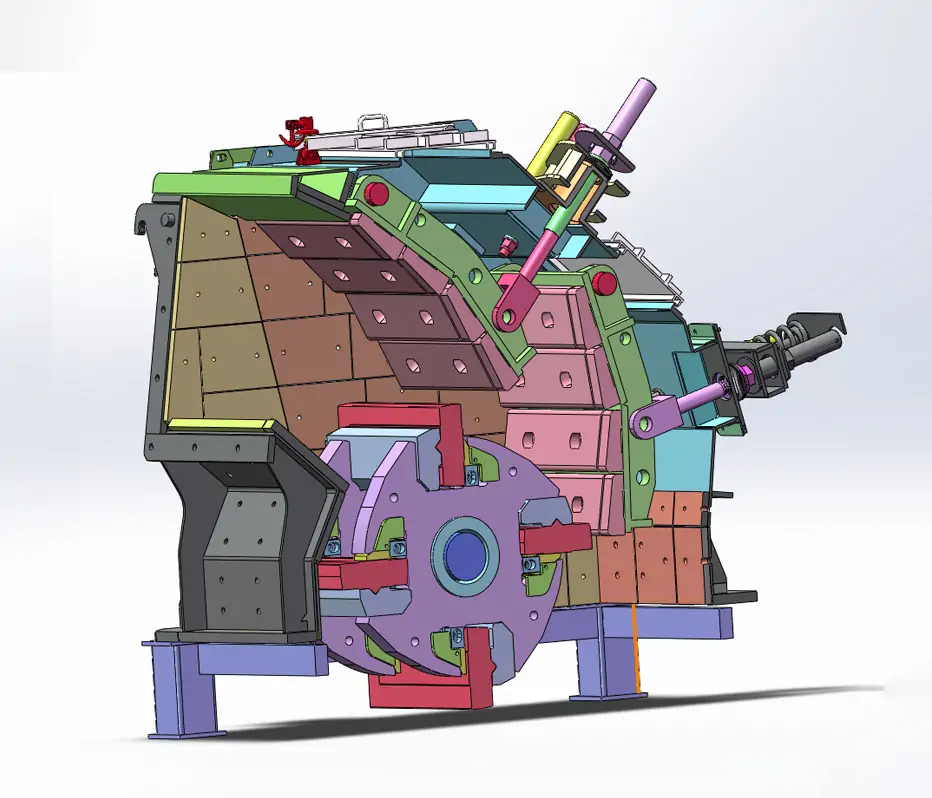

Product Introduction of PFC Impact Crusher

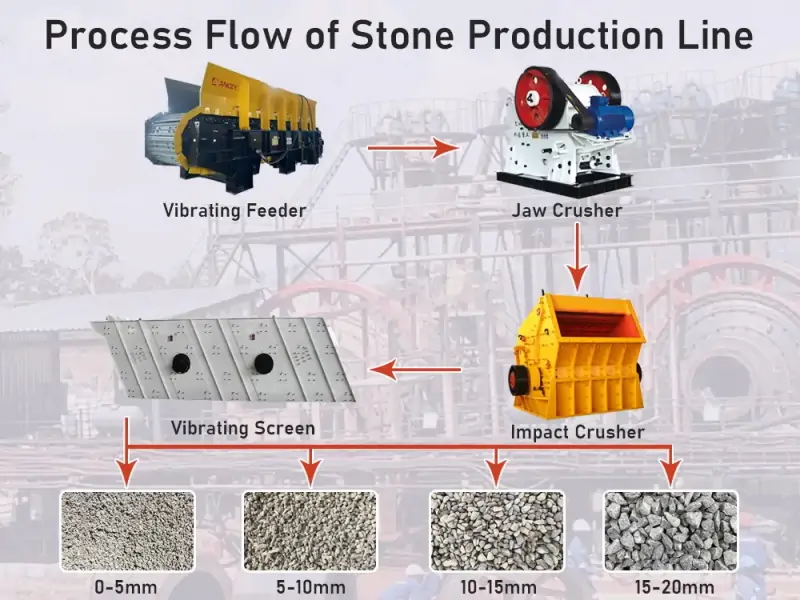

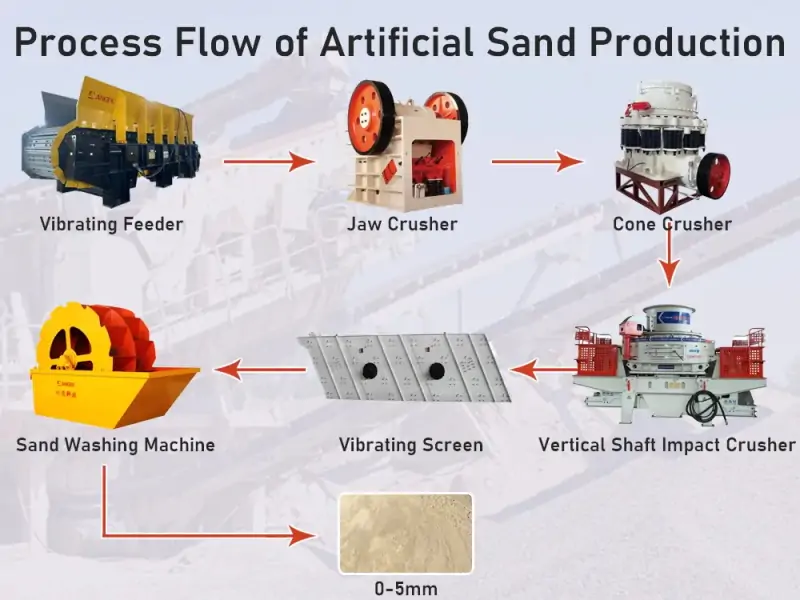

PFC Impact Crushers are the world’s leading rock and mineral processing equipment and have become the most popular. The rotor is the “heart” of the machine and plays a vital role in its operation. It has a heavy-duty rotor with a robust construction for higher inertia. The high wear-resistant material and the optimum crushing cavity make the crusher an outstanding performer. It is used in industrial sectors such as metallurgy, mining, cement, chemical, refractory, and ceramics. It is widely used in highway construction, water conservancy projects, building crushing, and mechanism sand processing. This crusher is suitable for crushing various soft and medium hard ores for coarse, medium, and fine crushing operations.

Advantages Of PFC Impact Crusher

PFC Impact Crusher is a new turbine impact crusher developed by BANGDE. It improves equipment performance and stone handling capacity. It is popular in the mineral, railway, energy, cement, chemical, and construction industries.

1. Excellent design, extra larger feeder opening

2. Powerful rotor structure, improve equipment processing capacity and stone crushing rate

3. High wear-resisting hammers reduce the consumption of wearing parts, save costs

Prices Of PFC Impact Crusher

The prices are different depend on different crusher models. As the leading mining crusher manufacturer with almost 30 year history in China, we will provide maximum preferential price and discount for you. Welcome to visit our company and factory.

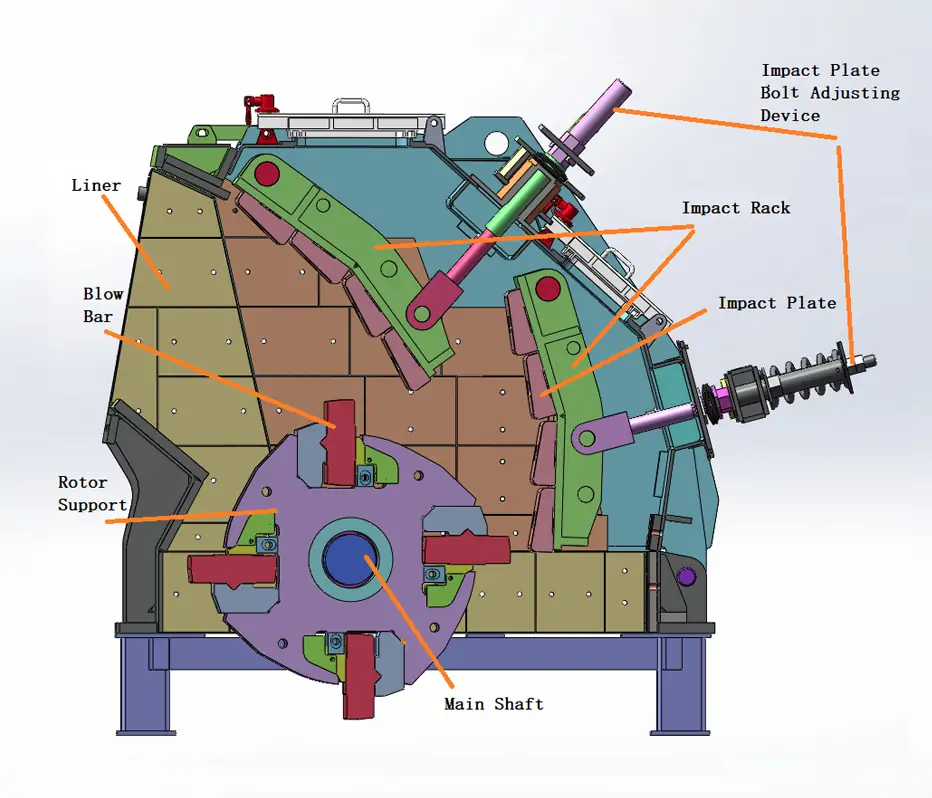

What is the working principle of PFC Impact Crusher?

When the material enters the hammer zone, it is crushed by the high-speed impact of the hammer and thrown to the impact device installed above the rotor to be crushed again. Then it is bounced back from the impacting liner to the plate hammer zone and crushed again. This process is repeated until the material is crushed to the required size and discharged from the lower part of the machine. The gap between the impacting frame and the rotor frame can be adjusted to change the material size and material shape. The machine adopts a spring safety device behind the impact plate. When the non-crushed material enters the crushing chamber, the front and rear impacting frame recedes, and the non-crushed material is discharged from the machine.

(Special note: It is strictly forbidden to enter non-crushable materials such as iron pieces, which will cause significant damage to the equipment)

Technical Advantages of PFC Impact Crusher

1. The crusher has an improved adjustment device, which is more convenient to operate.

2. The machine adopts a world-class manufacturing process and the highest-end production materials.

3. The machine’s two-chamber crushing simplifies the process when coarse and medium crushing operations are in progress.

4. Heavy-duty rotor design and strict testing methods ensure high-quality rotors.

Technical Data Of PFC Impact Crusher

| Type | Max. feeding size(mm) | Capscity(t/h) | Power(kw) | Dimesion(L*W*H)(mm) |

| CI1110 | 250 | 80-210 | 160 | 2826*2087*2285 |

| CI1213 | 300 | 100-280 | 200 | 2903*2530*2411 |

| CI1315 | 300 | 225-350 | 250 | 3320*2770*2535 |

| CI1520 | 350 | 360-600 | 2*(200-250) | 3450*3620*2770 |