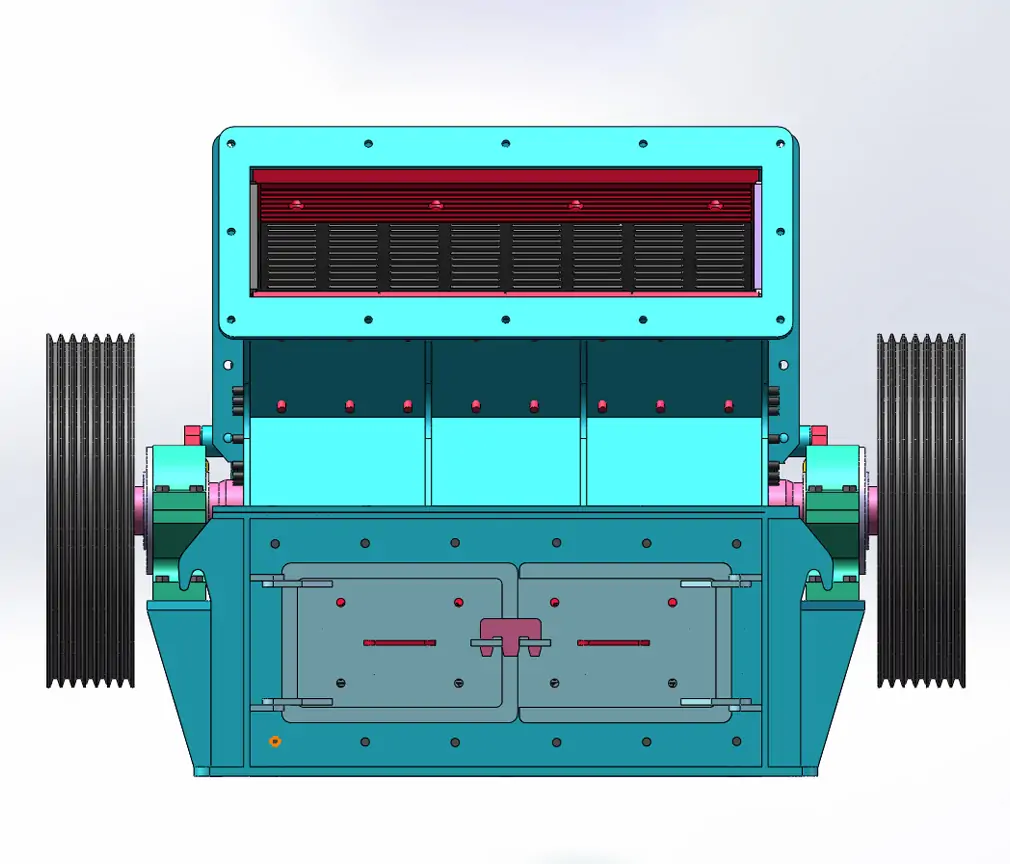

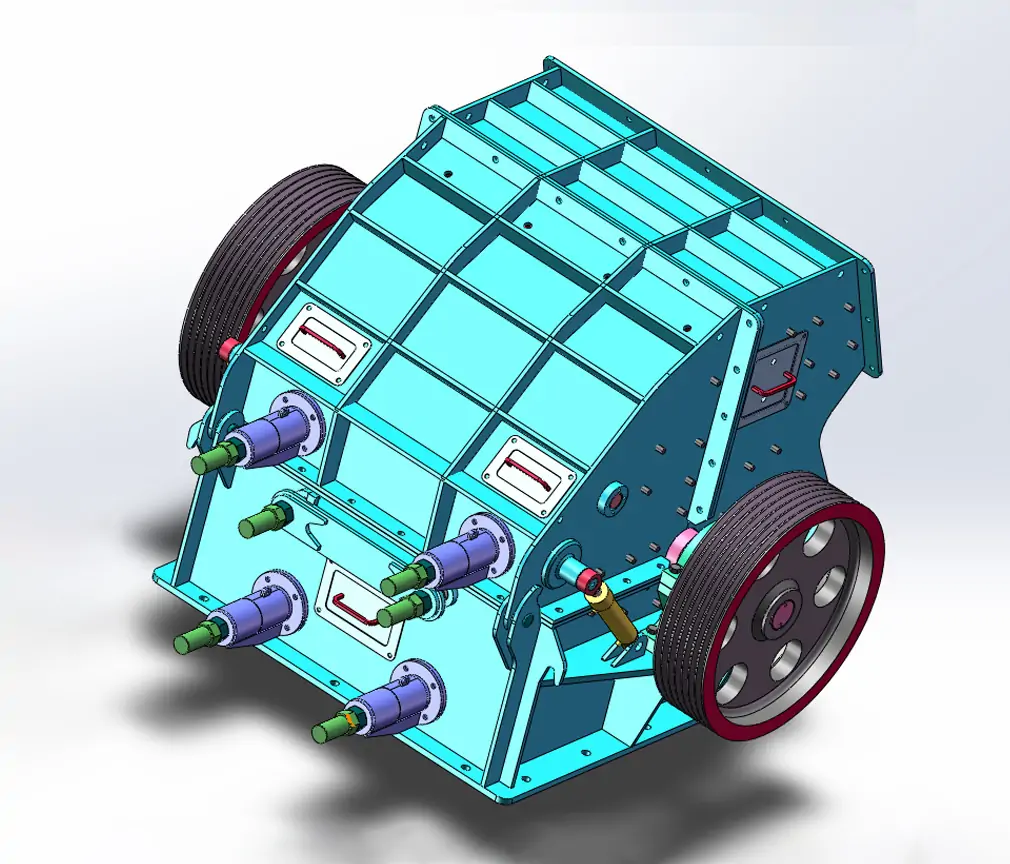

Product Introduction of ZS Sand Making Machine

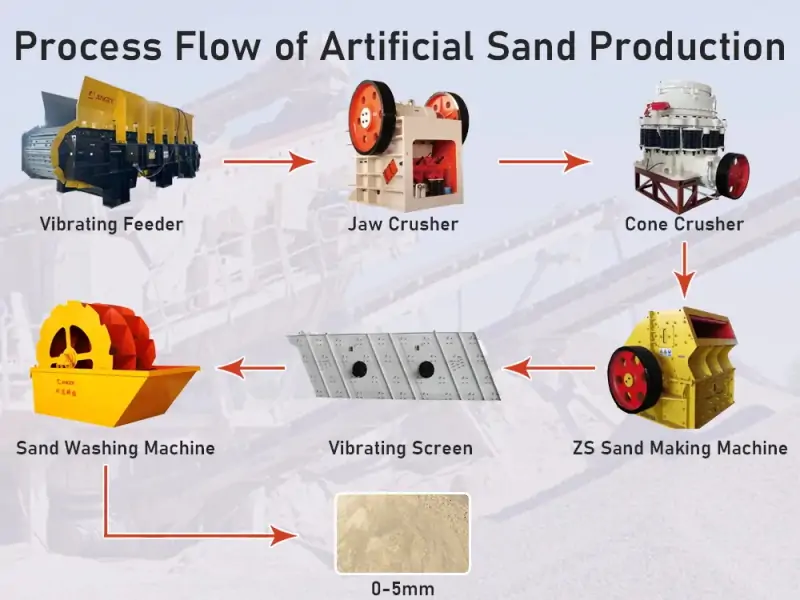

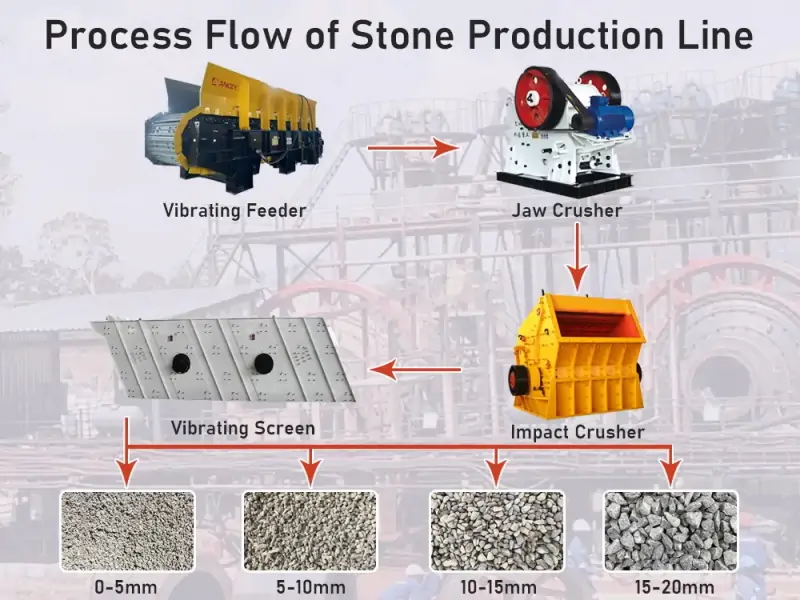

ZS Sand Making Machine is a secondary or tertiary fine crushing equipment. The applied materials are ores, rocks, and other materials. It is popular in mining, metallurgy, building materials, and mineral processing. It is also adopted in sand making, ceramics, and other material fine-crushing fields.

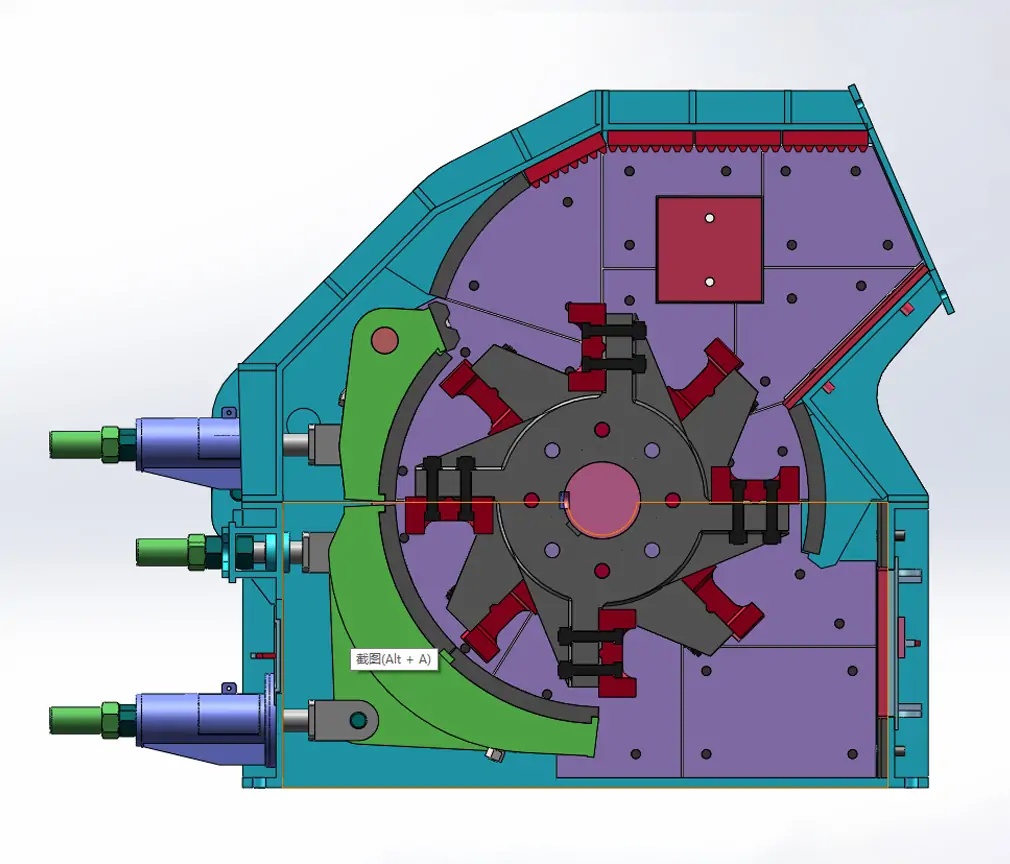

What is the working principle of ZS Sand Making Machine?

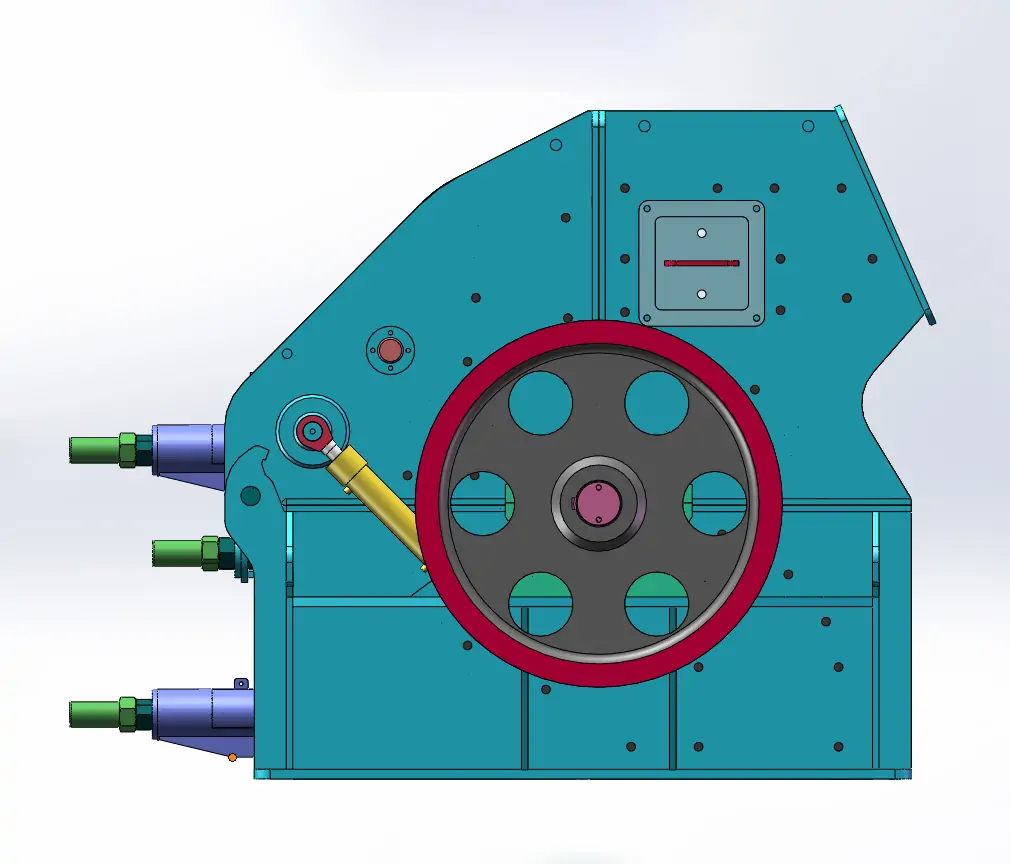

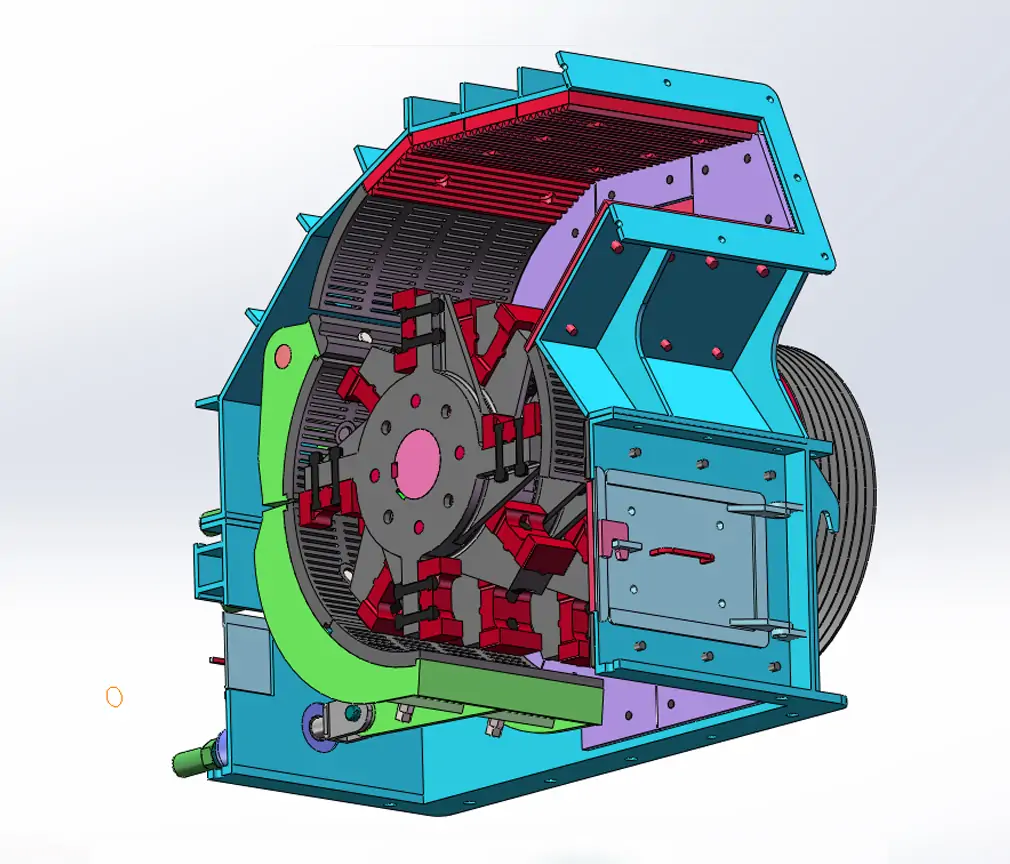

The electric motor drives the rotor to rotate at high speed through the v-belt and the big belt pulley. The material to be crushed is fed into the crushing chamber by the feeding equipment through the feeding port. The high-speed rotor drives the hammer head to strike the material first. After gaining kinetic energy, the material crushes into the impact plate at high speed to get the second crushing. After rebounding from the collision, the material is either struck again by the hammerhead or collides with other materials. In the collision process, the material gradually moves towards the movable impact plate in the lower part of the crushing cavity. When the size of the material is smaller than the gap between the hammer head and the movable impact plate, it will be discharged from the crushing cavity under the pressure of its weight and other materials, thus ending a complete crushing process. The discharged material is screened by the screening equipment and some of the materials larger than the selected standard are transported to the crusher for secondary crushing.

Prices of ZS Sand Making Machine

ZS Sand Making Machine prices are different depend on different crusher models. As the leading mining crusher manufacturer with almost 30 year history in China, we will provide maximum preferential price and discount for you. Welcome to visit our company and factory.

Technical Data Of ZS Sand Making Machine

| Type | Feeding size(mm) | Max. feeding size(mm) | Discharge range opening(mm) | Discharge size(mm) | Capacity(t/h) | Power(kw) |

| ZS0808 | 8000*300 | 160 | 5-20 | <5 | 30-40 | 55 |

| ZS1010 | 1000*350 | 180 | 5-20 | <5 | 40-60 | 90 |

| ZS1012 | 1200*350 | 180 | 5-20 | <5 | 70-100 | 110 |

| ZS1212 | 1200*450 | 180 | 5-20 | <5 | 80-120 | 132 |

| ZS1214 | 1500*450 | 190 | 5-20 | <5 | 100-140 | 160 |

| ZS1414 | 1500*500 | 190 | 5-20 | <5 | 120-180 | 200 |

| ZS1616 | 1600*550 | 200 | 5-20 | <5 | 170-210 | 250 |

| ZS1818 | 1800*700 | 200 | 5-20 | <5 | 250-270 | 315 |